Amtrak Roadway Worker Fatality

Bowie, Maryland

April 24, 2018

Accident Report

NTSB/RAR-21/02

PB2021-100935

National

Transportation

Safety Board

NTSB/RAR-21/02

PB2021-100935

Notation 67454

Adopted September 27, 2021

Railroad Accident Report

Amtrak Roadway Worker Fatality

Bowie, Maryland

April 24, 2018

National

Transportation

Safety Board

490 L’Enfant Plaza, S.W.

Washington, D.C. 20594

National Transportation Safety Board. 2021. Amtrak Roadway Worker Fatality, Bowie Maryland,

April 24, 2018. Publication Type NTSB/RAR-21/02. Washington, DC: NTSB.

Abstract: On April 24, 2018, about 8:58 a.m. local time, northbound Amtrak (National Railroad

Passenger Corporation) train 86 struck and killed an Amtrak rail gang watchman near the Bowie State

Train Station in Bowie, Maryland. The accident occurred on main track 1 at milepost 119.2 on Amtrak’s

Northeast Corridor. At the time of the accident, main track 2 was out of service under a continuous track

outage for track maintenance, and the adjacent tracks immediately to the east and west of main track 2

(main tracks 1 and 3, respectively) were in service for train movements. Three watchmen were protecting

the roadway workers and watching for trains moving on adjacent tracks to warn workers of approaching

trains. One watchman was positioned near the boarding platform, another was positioned in a nearby

curve, and the third watchman was positioned toward the end of the curve, near a work gang of welders.

The third watchman was the employee struck by the train. No passengers or crewmembers on Amtrak

train 86 were injured. The National Transportation Safety Board (NTSB) identified the following safety

issues: inadequate site-specific safety risk assessment, unsafe train speeds in established work zones, and

ineffective roadway worker protection. As a result of this investigation, the NTSB makes safety

recommendations to the Federal Railroad Administration; Amtrak; and Amtrak and all Class I Railroads.

NTSB also reiterated a recommendation to Amtrak and reiterated and classified a recommendation to the

Federal Railroad Administration.

The National Transportation Safety Board (NTSB) is an independent federal agency dedicated to promoting

aviation, railroad, highway, marine, and pipeline safety. Established in 1967, the agency is mandated by Congress

through the Independent Safety Board Act of 1974, to investigate transportation accidents, determine the probable

causes of the accidents, issue safety recommendations, study transportation safety issues, and evaluate the safety

effectiveness of government agencies involved in transportation. The NTSB makes public its actions and decisions

through accident reports, safety studies, special investigation reports, safety recommendations, and statistical

reviews.

The NTSB does not assign fault or blame for an accident or incident; rather, as specified by NTSB regulation,

“accident/incident investigations are fact-finding proceedings with no formal issues and no adverse parties … and

are not conducted for the purpose of determining the rights or liabilities of any person” (Title 49 Code of Federal

Regulations section 831.4). Assignment of fault or legal liability is not relevant to the NTSB’s statutory mission to

improve transportation safety by investigating accidents and incidents and issuing safety recommendations. In

addition, statutory language prohibits the admission into evidence or use of any part of an NTSB report related to an

accident in a civil action for damages resulting from a matter mentioned in the report (Title 49 United States Code

section 1154(b)).

For more detailed background information on this report, visit the NTSB investigations website and search for

NTSB accident ID RRD18FR006. Recent publications are available in their entirety on the NTSB website. Other

information about available publications also may be obtained from the website or by contacting—

National Transportation Safety Board

Records Management Division, CIO-40

490 L’Enfant Plaza, SW

Washington, DC 20594

(800) 877-6799 or (202) 314-6551

Copies of NTSB publications may be downloaded at no cost from the National Technical Information Service, at the

National Technical Reports Library search page, using product number 2020-101009. For additional assistance,

contact—

National Technical Information Service

5301 Shawnee Rd. Alexandria, VA 22312

(800) 553-6847 or (703) 605-6000

NTIS website

67454

Contents

Figures ........................................................................................................................................... iii

Tables ............................................................................................................................................ iv

Abbreviations and Acronyms .......................................................................................................v

Executive Summary ..................................................................................................................... vi

Probable Cause............................................................................................................................... vi

Safety Issues.................................................................................................................................. vii

Findings......................................................................................................................................... vii

Recommendations ........................................................................................................................ viii

New Recommendations ........................................................................................................ viii

Previous Recommendation Reiterated in this Report ........................................................... viii

Previous Recommendation Reiterated and Classified in this Report ..................................... ix

1. Factual Information .................................................................................................................1

1.1. Accident ....................................................................................................................................1

1.2. Site Description ........................................................................................................................3

1.3. Work Project .............................................................................................................................4

1.4. Site-Specific Safety Work Plan ................................................................................................5

1.5. Work Zone Hazards ..................................................................................................................6

1.5.1. Physical Environment ....................................................................................................6

1.5.2. Sound Levels at the Time of the Accident .....................................................................7

1.6. Amtrak Train 86 .......................................................................................................................7

1.7. Personnel Information ..............................................................................................................7

1.7.1. Rail Gang Watchman .....................................................................................................7

1.7.2. Amtrak Train 86 Engineer .............................................................................................8

1.8. Roadway Worker Protection ....................................................................................................9

1.8.1. Amtrak Special Instructions ...........................................................................................9

1.8.2. Train Approach Warning .............................................................................................10

1.8.3. Working Limits ............................................................................................................10

1.8.4. Positive Train Control ..................................................................................................10

1.9. Postaccident Inspections .........................................................................................................11

1.9.1. Sight Distance Observations ........................................................................................11

1.10. Postaccident Actions ....................................................................................................12

2. Analysis ...................................................................................................................................13

2.1. Introduction ............................................................................................................................13

2.2. Site-Specific Safety Work Plan ..............................................................................................14

2.3. Train Speeds in Work Zones ..................................................................................................16

2.4. Roadway Worker Protection ..................................................................................................17

NTSB Railroad Accident Report

ii

3. Findings ...................................................................................................................................20

3.1. Conclusions ............................................................................................................................20

3.2. Probable Cause .......................................................................................................................20

4. Recommendations ..................................................................................................................21

4.1 New Recommendations ..........................................................................................................21

4.2. Previous Recommendation Reiterated in this Report .............................................................21

4.3 Previous Recommendation Reiterated and Classified in this Report .....................................22

Appendixes....................................................................................................................................23

Appendix A. The Investigation ......................................................................................................23

Appendix B. Consolidated Recommendation Information ............................................................24

Appendix C. Prior Train Approach Warning Accidents ................................................................26

Providence, Rhode Island .......................................................................................................26

Edgemont, South Dakota ........................................................................................................26

Queens Village, New York .....................................................................................................27

References .....................................................................................................................................28

NTSB Railroad Accident Report

iii

Figures

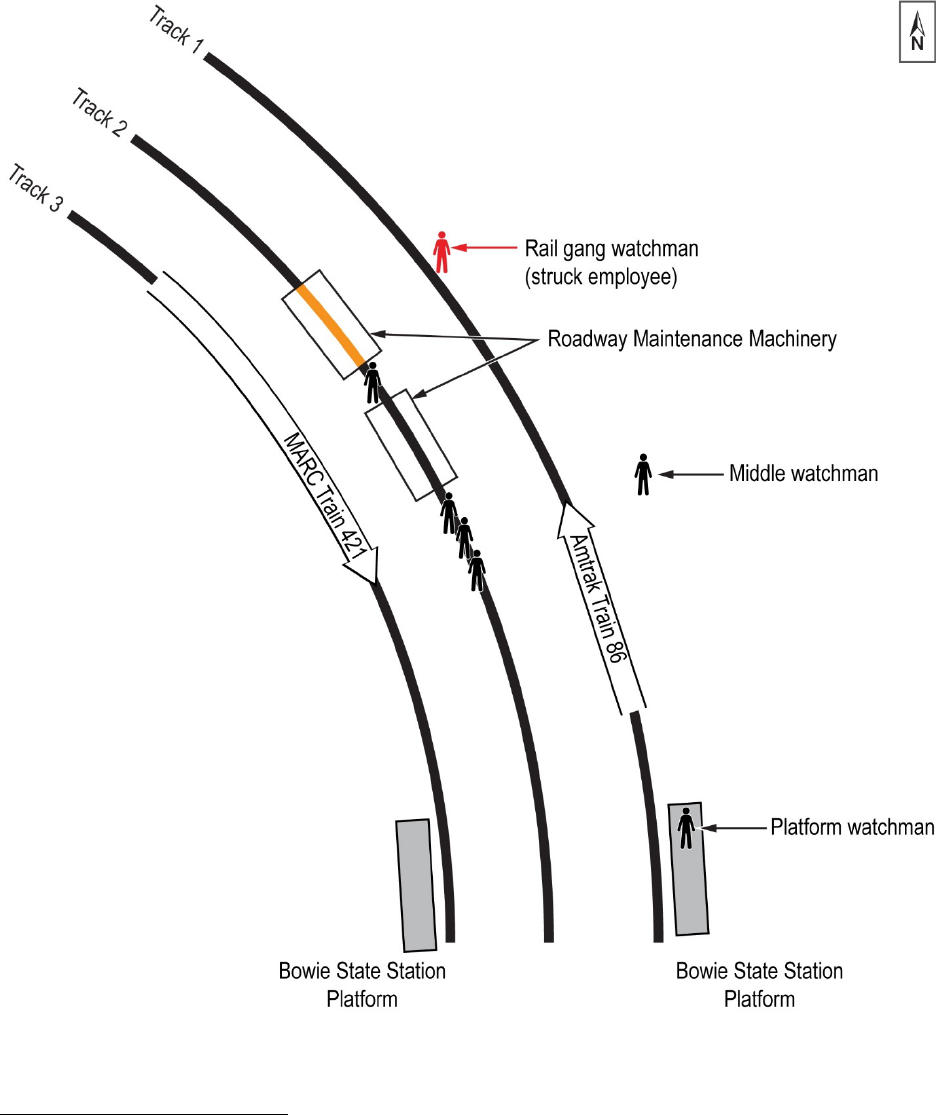

Figure 1. Graphic of accident site. ................................................................................................. 2

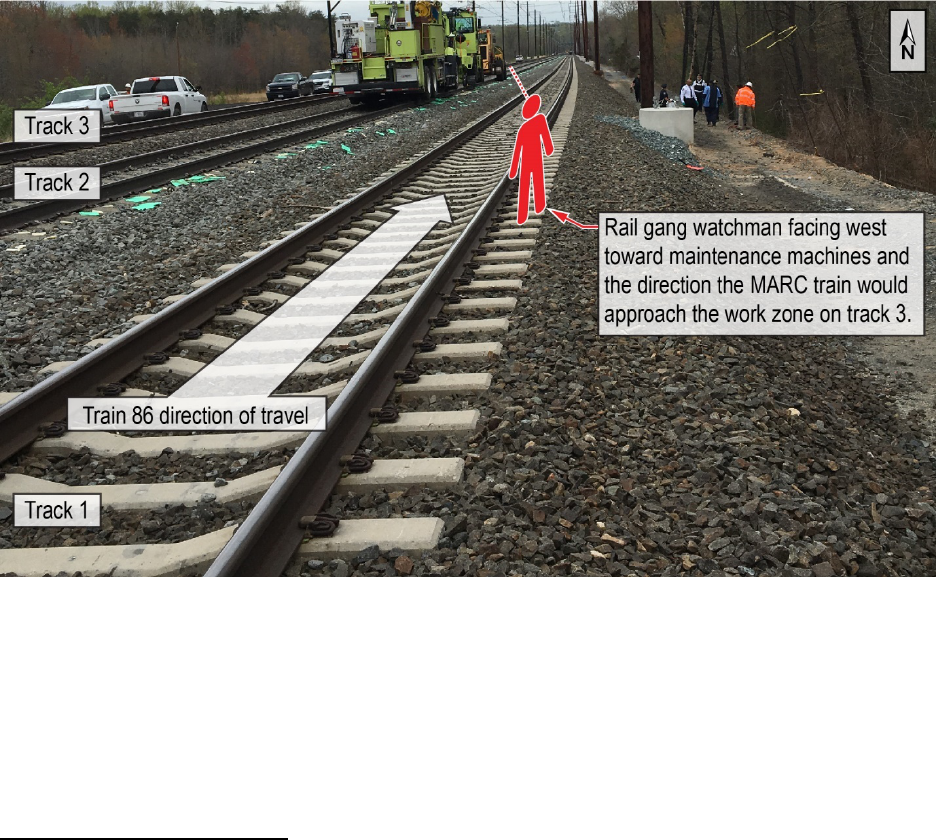

Figure 2. Photograph of the accident area, facing north. ............................................................... 6

NTSB Railroad Accident Report

v

Abbreviations and Acronyms

ACSES Advanced Civil Speed Enforcement System

Amtrak National Railroad Passenger Corporation

CFR Code of Federal Regulations

FAMES Fatality Analysis of Maintenance-of-Way Employees and Signalmen

FRA Federal Railroad Administration

MARC Maryland Area Rail Commuter

MAS maximum authorized speed

MP milepost

NTSB National Transportation Safety Board

NORAC Northeast Operating Rules Advisory Committee

PTC positive train control

RWIC roadway worker-in-charge

RWP roadway worker protection

SSSWP site-specific safety work plan

TAW train approach warning

NTSB Railroad Accident Report

vi

Executive Summary

On April 24, 2018, about 8:58 a.m. local time, northbound Amtrak train 86 struck and

killed an Amtrak rail gang watchman near the Bowie State Train Station in Bowie, Maryland. The

accident occurred on main track 1 at milepost 119.2 on the Philadelphia to Washington line,

located on Amtrak’s Northeast Corridor. At the time of the accident, main track 2 was out of

service under a continuous track outage for track maintenance, and the adjacent tracks immediately

to the east and west of main track 2 (main tracks 1 and 3, respectively) were in service for train

movements. Three watchmen were protecting the roadway workers and watching for trains moving

on adjacent tracks to warn workers of approaching trains. One watchman was positioned near the

boarding platform, another was positioned in a nearby curve, and the third watchman was

positioned toward the end of the curve, near a work gang of welders. The third watchman was the

employee struck by the train. No passengers or crewmembers on Amtrak train 86 were injured.

1

Amtrak train 86 departed Washington, D.C.’s Union Station about 8:40 a.m., destined for

New York’s Penn Station. The train was authorized to operate on main track 1 at maximum

authorized speeds between 105 and 110 mph. The accident occurred when Amtrak train 86 entered

the work zone. Immediately before Amtrak train 86 arrived at the work zone, Maryland Area Rail

Commuter train 421 was traveling southbound through the work zone on main track 3, preparing

to service the southbound passenger platform at the Bowie State Train Station. When Amtrak

train 86 passed the Bowie State Train Station on main track 1, the engineer noticed that the rail

gang watchman was standing too close to the track’s edge, facing the roadway workers on main

track 2 and the passing Maryland Area Rail Commuter train on main track 3. He was not looking

toward Amtrak train 86’s approach and did not respond to the horn from the train nor the warnings

from the other watchmen. The engineer applied emergency train braking, slowing the train to

98 mph, before striking and killing the rail gang watchman.

Probable Cause

The National Transportation Safety Board determines that the probable cause of the Bowie

accident was Amtrak’s insufficient site-specific safety work plan for the Bowie project that (1) did

not consider the multiple main tracks in a high noise environment and (2) did not provide the rail

gang watchman with a safe place to stand with level footing and sufficient sight distance to perform

his duties, which led the rail gang watchman to stand on an active track in a work zone in the path

of Amtrak train 86. Contributing to this accident was Amtrak’s decision to use train approach

warning for roadway worker protection in lieu of the protections that could have been provided by

the positive train control system.

1

For more information, see the factual information and analysis sections of this report. Additional information

can be found in the public docket for this National Transportation Safety Board (NTSB) accident investigation (case

number RRD18FR006) by accessing the Accident Dockets link at www.ntsb.gov

. For information about our safety

recommendations, see the CAROL Safety Recommendation Database at the same website.

NTSB Railroad Accident Report

vii

Safety Issues

• Inadequate site-specific safety risk assessment. Although Amtrak had developed a

site-specific safety work plan for its maintenance project, an analysis of that plan revealed

that Amtrak’s safety risk assessment did not identify and mitigate obvious risks and dangers

placed on roadway workers, specifically, watchmen being struck by trains and other

on-track equipment in a high-density, high-decibel, high-speed, multiple main track work

environment.

• Unsafe train speeds in established work zones. On the day of the accident, trains were

permitted to operate at speeds up to 125 mph through the work zone. Amtrak’s policy that

permits the operation of trains at high speeds through work zones continued after the April

3, 2016, accident in Chester, Pennsylvania, in which a train collided with maintenance-of-

way equipment, killing 2 people and injuring 39 others.

• Ineffective roadway worker protection. Although Federal Railroad Administration

regulations and Amtrak policies permit the use of train approach warning to establish

on-track protection for roadway workers, Amtrak’s decision to use this form of protection

in a high-risk area allowed roadway workers to be exposed to the dangers of simultaneous

bidirectional train movements at speeds up to 125 mph. The decision to use train approach

warning protection permitted trains to operate through the multiple main track work zone

at high speeds, solely relying on the situational awareness of the watchmen to provide

warnings to workers.

Findings

• None of the following were factors in the accident: (1) mechanical condition of the train;

(2) train handling and warnings from the engineer of Amtrak train 86; (3) employee fatigue;

(4) employee training; (5) rail gang watchman impairment from alcohol and other

tested-for drugs; and (6) cell phone usage.

• The rail gang watchman was most likely standing on the crosstie ends to obtain stable

footing and to improve the visibility between himself and the roadway workers, as well as

to improve his ability to see approaching trains from the north.

• The rail gang watchman likely did not realize that he was in imminent danger from

northbound Amtrak train 86 because his attention was focused on warning the rail gang of

the approaching southbound Maryland Area Regional Commuter train.

• Amtrak’s site-specific safety work plan did not consider all work zone hazards for roadway

workers, including the watchmen, because it did not identify the specific hazards relating

to the multiple track work zone, such as simultaneous train movements, steep ballast

shoulders, high noise levels, and trains operating at high speeds.

NTSB Railroad Accident Report

viii

• Had Amtrak required trains to approach at significantly slower speeds through the Bowie

work zone, the rail gang watchman would have had more time to become aware of the

approaching train and relocate to a place of safety.

• Train approach warning is a weak system of on-track safety that fails to protect roadway

workers, including watchmen, in controlled track territory.

• Had Amtrak established working limits or speed restrictions on main tracks 1 and 3 that

enabled the protections available under positive train control, rather than relying on the use

of train approach warning, the accident may have been prevented.

Recommendations

The National Transportation Safety Board proposes the following new safety

recommendations:

New Recommendations

To the Federal Railroad Administration:

Modify Title 49 Code of Federal Regulations Part 214 to prohibit the use of train approach

warning in controlled track territory during planned maintenance and inspection activities.

(R-21-3)

To Amtrak (National Railroad Passenger Corporation):

Modify your site-specific safety work plan to require all work zone hazards for roadway

workers and watchmen be identified and mitigated, including hazards associated with multiple

main track work zones. (R-21-4)

To Amtrak and all Class I Railroads:

Eliminate the use of train approach warning protection in controlled track territory during

planned maintenance and inspection activities. (R-21-5)

Previous Recommendation Reiterated in this Report

The National Transportation Safety Board proposes reiterating the following safety

recommendation:

To Amtrak:

Conduct a risk assessment for all engineering projects and use the results to issue significant

speed restrictions for trains passing any engineering project that involves safety risks for

NTSB Railroad Accident Report

ix

workers, equipment, or the traveling public, such as ballast vacuuming, as part of a

risk-mitigation policy. (R-17-23)

This safety recommendation is classified “Open⸻Acceptable Response.”

Previous Recommendation Reiterated and Classified in this Report

The National Transportation Safety Board proposes classifying the following safety

recommendation:

To the Federal Railroad Administration:

Define when the risks associated with using train approach warning are unacceptable and

revise Title 49 Code of Federal Regulations 214.329 to prohibit the use of train approach

warning when the defined risks are unacceptable. (R-20-6)

This safety recommendation was previously classified “Open⸻Initial Response Received”

on April 16, 2021. This recommendation is now classified “Open⸺Unacceptable Response.”

NTSB Railroad Accident Report

1

1. Factual Information

1.1. Accident

On April 24, 2018, about 8:58 a.m. local time, northbound National Railroad Passenger

Corporation (Amtrak) train 86 struck and killed an Amtrak watchman in Bowie, Maryland.

1

No

passengers or crewmembers on Amtrak train 86 were injured. The accident occurred on main

track 1 at milepost (MP) 119.2 on the Philadelphia to Washington line, located on Amtrak’s

Northeast Corridor, about 1,500 feet north of the Bowie State Train Station.

2

The accident occurred

in three-track signal-controlled territory, with many curves, an active passenger train station, and

maximum authorized speeds (MAS) up to 105 mph on main track 1 and 125 mph on main track 3.

3

Scheduled maintenance work began on March 9, 2018, and main track 2, the center track

in a multiple main track territory, was placed out of service under a continuous track outage

between Bowie State, MP 120.5, and Grove, MP 112.4. Trains moving through the work zone

were operating under the authority of two-way track signal indications and dispatcher control.

4

Three watchmen were positioned along the east side of main track 1 with instructions to use train

approach warning (TAW) to protect the roadway workers and watch for trains on the two tracks

in service that ran immediately adjacent to the working limits: main track 1 and main track 3,

which were east and west, respectively, of main track 2.

5

Figure 1 shows the accident site,

including the location of the three watchmen. The struck watchman (referred to in this report as

the rail gang watchman) was positioned along main track 1 protecting a group of track welders

working on main track 2. One watchman (referred to in this report as the platform watchman), was

posted at the Bowie State Train Station platform; this position allowed him to detect trains

approaching the working limits from the south on main tracks 1 and 3. The other watchman

(referred to in this report as the middle watchman), was posted along the sloped ballast shoulder,

about 800 feet north of the watchman posted at the Bowie State Train Station. From this location,

the middle watchman had sufficient time to detect trains approaching the working limits from the

north. The rail welding foreman positioned the rail gang watchman at MP 119.2, directly across

from the rail welders and roadway maintenance machinery because there was additional noise due

1

A watchman is designated by the roadway worker-in-charge (RWIC) and can be any member of the roadway

worker work group who has received the proper training, which is offered annually.

2

This location consists of three main tracks.

3

Maximum authorized speed (MAS) is the highest speed permitted for the movement of trains permanently

established by timetable/special instructions, general order, or track bulletin.

4

Two-way track signal indication (Northeast Operating Rules Advisory Committee [NORAC] rule 261) allows

trains to operate on the same track in both directions.

5

(a) Train approach warning is a method of establishing on-track safety by warning roadway workers of the

approach of trains in ample time for them to move to or remain in a place of safety. (b) Working limits refers to a

segment of track with definite boundaries within which trains and engines may move only as authorized by the

roadway worker in control of that segment of track.

NTSB Railroad Accident Report

2

to the equipment and the watchman would be in a better position to get the attention of the

welders.

6

At this location he was about 660 feet north of the middle watchman.

Figure 1. Graphic of accident site.

6

Roadway maintenance machinery is a device powered by any means of energy other than hand power which is

being used on or near railroad track for maintenance, repair, construction or inspection of track, bridges, roadway,

signal, communications, or electric traction systems. Roadway maintenance machines may have road or rail wheels

or may be stationary. Welding track and rail heaters are examples of roadway maintenance machinery.

NTSB Railroad Accident Report

3

Immediately before Amtrak train 86 arrived at the work zone, Maryland Area Rail

Commuter (MARC) train 421 was traveling southbound on main track 3 and was scheduled to

service the southbound passenger platform at the Bowie State Train Station at 8:58 a.m. As it

approached the roadway workers working on main track 2, the train began to reduce its speed to

service the station on main track 3. (See figure 1.) The watchmen, including the rail gang

watchman, detected the approaching MARC train and alerted the roadway workers by blowing

their hand-held air horns and raising their orange watchman’s warning discs.

7

Work personnel told

investigators that the roadway maintenance machinery operators then blew their

equipment-mounted air horns to provide additional audible warnings.

As the last three cars of MARC train 421 were passing the roadway workers, northbound

Amtrak train 86 approached the work zone on main track 1 at a speed of about 99 mph. The middle

watchman later told the National Transportation Safety Board (NTSB) that he noticed the train but

that its approach “caught him off guard” because there was no break between the audible alerts

from the other watchmen for the MARC train, and he did not hear another horn to alert him. He

then noticed that the rail gang watchman was standing on the edge of the main track 1 ties, fouling

the track, and did not appear to be aware of the approaching northbound train.

8

The middle

watchman said that he attempted to alert the rail gang watchman but could not get his attention.

Forward-facing image recordings from Amtrak train 86 showed that the rail gang watchman was

wearing a hooded sweatshirt with the hood up underneath his hard hat with his left shoulder facing

Amtrak train 86.

According to event recorder data, as Amtrak train 86 entered the work zone, the engineer

sounded the train’s horn and warning bell in a series of five warning blasts, lasting between 1 and

5 seconds each, between 8:57:40 a.m. and 8:58:10 a.m. The engineer later told the NTSB that he

noticed that the rail gang watchman was standing too close to the track’s edge, facing the roadway

workers on main track 2 and the MARC train on main track 3, so the rail gang watchman did not

see the train’s approach. The engineer initiated emergency train braking, slowing the train down

to 98 mph, before striking and killing the rail gang watchman.

1.2. Site Description

The accident site consisted of three main line-controlled tracks that ran parallel in a

timetable north-south direction.

9

The tracks were equipped with Amtrak’s Advanced Civil Speed

Enforcement System (ACSES), a positive train control (PTC) technology used on Amtrak

7

Details of the job responsibilities of watchmen are found at Title 49 Code of Federal Regulations (CFR) 214.329

“Train Approach Warning Provided by Watchmen/Lookouts.”

8

Fouling a track means the placement of an individual or an item of equipment in such proximity to a track that

the individual or equipment could be struck by a moving train or on-track equipment or, in any case, is within 4 feet

of the field side of the near running rail.

9

(a) Controlled track means track upon which the railroad's operating rules require that all movements of trains

must be authorized by a train dispatcher or a control operator. (b) Positive train control (PTC) is an advanced train

control system that uses communication-based and processor-based technology and must reliably and functionally

prevent train-to-train collisions, overspeed derailments, incursions into established work zone limits, and movements

of trains through switches in the wrong position. (c) Timetable direction refers to the geographical origin and

termination locations of the trains. Often the track will be oriented on an opposing compass direction.

NTSB Railroad Accident Report

4

properties.

10

The tracks are geographically situated east to west with main track 1 to the east and

main track 3 to the west. (See figure 1.)

Trains operating on main track 1 were under the movement authority of a permanent speed

restriction of 105 mph between MP 121.0 and MP 119.0. Train speeds could increase to 110 mph

between MP 119.0 and MP 118.4, north of the accident location. Trains operating on main track 3

had a MAS of 125 mph. Trains operating through the work zone were under the authority of

two-way track signal indications and dispatcher control. In multiple track territories, trains may

operate on any track, at any time, and in any direction. There were no established work zone speed

restrictions for trains operating on main tracks 1 and 3 through the work zone.

1.3. Work Project

On March 9, 2018, main track 2 was placed out of service under a continuous

24-hour-per-day/7-day-per-week track outage between Bowie State, MP 120.5, and Grove,

MP 112.4, so that the Amtrak maintenance-of-way roadway workers could perform production

track undercutting and other maintenance and repair work of main track 2.

11

According to interviews with the roadway workers, on the morning of the accident, the

undercutter roadway workers met for roll call and job assignments. The track supervisor met with

his foremen and assigned the undercutter surfacing foreman as the roadway worker-in-charge

(RWIC) of the working limits. At 7:00 a.m., the roadway workers arrived at their work locations

where the rail gang foreman (referred to as the employee-in-charge in this report), conducted an

initial job safety briefing with the roadway workers.

12

This initial briefing was one of two required

briefings.

13

The details of the briefing included information on the work location, personal

protective equipment requirements, job duties, and Amtrak’s safety rule of the day. All workers

who were in attendance acknowledged their understanding of the job safety briefing by signing

the job briefing documentation sheet.

At 7:50 a.m., the employee-in-charge received a text message from the RWIC that included

a copy of the Form D for track 2, which allowed the roadway work crew to control the track, along

with a message granting the work gang permission to begin work.

14

About 8:00 a.m., the

employee-in-charge conducted the on-track safety briefing with the roadway workers.

15

The focus

10

Amtrak has activated the Advanced Civil Speed Enforcement System (ACSES) on the tracks it owns in the

Northeast Corridor and on the Amtrak-owned portion of the Michigan line. ACSES, in combination with cab signaling,

is a PTC cab-signaling system designed to prevent train-to-train collisions, protect against overspeed, and protect work

crews with temporary speed restrictions. It meets the Federal Railroad Administration’s (FRA) requirements of a PTC

system.

11

(a) The accident occurred in the south working limits of the undercutter project. (b) An undercutter is an

on-track machine that removes ballast from beneath the track so it can be cleaned.

12

Employee-in-charge is an employee responsible for a work group under the overarching authority of the RWIC.

13

Title 49 CFR 214.315 “Supervision and Communication.”

14

Form D is a form that grants the RWIC authority of the track, rather than the dispatcher. It basically provides

the name of a contact person with authority of the track in case of an emergency. Although main track 2 was under a

continuous outage, Amtrak’s internal processes required that a Form D be submitted on a daily basis.

15

On-track safety means a state of freedom from the danger of being struck by a moving railroad train or other

railroad equipment, provided by operating and safety rules that govern track occupancy by personnel, trains, and

equipment.

NTSB Railroad Accident Report

5

points of this briefing included the track outage number, protective limits and type of on-track

safety for main track 2, adjacent track speeds, adjacent track on-track protection, total number of

needed watchmen, and the predetermined place(s) of safety.

16

All roadway workers who were in

attendance, including the rail gang watchman, acknowledged their understanding of the on-track

safety briefing by signing the on-track safety briefing documentation sheet.

1.4. Site-Specific Safety Work Plan

In March 2018, Amtrak developed a 16-page site-specific safety work plan (SSSWP) for

the Bowie project in collaboration with management, supervisors, maintenance employees, and

the safety department. The SSSWP’s objective was to identify existing or potential hazards and

determine how best to eliminate, control, or minimize all identified hazards to an acceptable level

of risk.

One of the hazards identified in the SSSWP for the Bowie project was “On-Track

Protection.” The mitigation for this identified hazard was to “comply with all RWP [roadway

worker protection] rules and procedures.” However, the SSSWP did not contain any detailed

language about the RWP rules and procedures for the work site or the type of on-track safety to be

used for adjacent on-track protection. (See section 1.8 for more information on the RWP rule.) The

SSSWP did specifically address the undercutting between MP 120.5 and MP 112.2, stating that

the project was starting in “hot spot” territory, where extra watchmen would be required to

effectively provide the required RWP protection to the roadway workers.

Amtrak uses the term “hot spots” to identify locations along the railroad where additional

on-track safety is required due to watchmen line-of-sight issues, obstructions, work zone

characteristics, close clearing/no clearing points, and work zone noise levels. The SSSWP did not

define and provide guidance on what the “hot spots” were in the Bowie work zone, the risks to

roadway workers when working within this “hot spot” territory, or the risk mitigations to

implement when working within the “hot spot” territory. Moreover, in 2014, some 4 years before

this accident, Amtrak removed all training on “hot spots” from its RWP curriculum, and in 2017,

Amtrak removed all references of “hot spot” from its RWP manual. Although not defined, the term

is referenced within the Bowie undercutter project SSSWP and Amtrak’s job safety and on-track

job safety briefing forms.

When the NTSB interviewed the RWIC, he was asked whether he requested foul time for

the work zone. Foul time is a method of establishing working limits on controlled track in which

a roadway worker is notified by the train dispatcher or control operator that no trains will operate

within a specific segment of controlled track until the roadway worker reports clear of the track,

as prescribed in Title 49 Code of Federal Regulations (CFR) 214.323 “Foul Time.” (Working

limits are further discussed in section 1.8.3.) The RWIC indicated that, because it was rush hour,

he would not have been granted foul time for the work zone at the time of the accident. The RWIC

further elaborated that the time between trains, the length of the work zone (8 miles), and the

16

A predetermined place of safety is the specific location that a roadway worker must occupy upon receiving a

watchman’s warning of approaching train movements on a track.

NTSB Railroad Accident Report

6

MARC train stops within the working limits would have hindered his ability to be granted foul

time.

1.5. Work Zone Hazards

1.5.1. Physical Environment

During an examination of the accident scene, the NTSB noted that the ballast shoulder was

steep at the location where the rail gang watchman was posted and did not provide stable footing.

17

Figure 2 shows the work environment. The NTSB asked the platform watchman about the rail

gang watchman’s position on the steep ballast. The platform watchman indicated that, in general,

it was difficult to find stable footing anywhere along the steep ballast shoulder throughout the work

zone.

Figure 2. Photograph of the accident area, facing north.

The middle watchman indicated that the steep ballast shoulder was uncomfortable to stand

on while watching for trains. The slope was steep enough that standing on the rocks that made up

the ballast caused unstable footing.

Another roadway worker, who at times performed watchman duties, told investigators that

near where the accident occurred, he felt it was necessary to stand right on the edge of the ties

17

Ballast is material selected for placement on the roadbed, usually crushed stone, for the purpose of holding the

track in line and at surface. It is applied to the roadbed to hold track to proper alignment.

NTSB Railroad Accident Report

7

because the steep ballast slope made it too difficult to safely stand and properly watch for trains.

He also suggested to the NTSB that watchman platforms be built to reduce the safety hazards of

unstable footing. Another employee stated that when watching for trains, he often found it

necessary to move and pack the ballast around with his feet to make “step like” indentations in the

steep ballast slope. He stated that when a train approached, he usually would go behind a catenary

pole for added protection due to the flying debris and dust that the train kicked up.

18

1.5.2. Sound Levels at the Time of the Accident

The middle watchman provided his perspective to the NTSB about sound levels at the time

of the accident. Noises generated from the passing train horns, roadway maintenance machine

horns, and air horns from the platform watchman and middle watchman were prevalent. The

middle watchman reported that he was caught “off guard” when he saw Amtrak train 86 coming

from the south because he did not hear the platform watchman blow his horn. He said that the

watchmen were still blowing their horns for the MARC train that had entered the work zone from

the north, but he did not hear another horn to alert everyone to the second train approaching from

the south. He said that when he noticed Amtrak train 86 entering the area, he sounded his horn in

an attempt to get the attention of the rail gang watchman to his north. The middle watchman

indicated that it was possible that the struck watchman did not hear his horn, which was his only

means of getting his attention.

1.6. Amtrak Train 86

Amtrak train 86, a Northeast Regional Direct train, departed Washington, D.C.’s Union

Station about 8:40 a.m. on the day of the accident, destined for New York’s Penn Station. It

consisted of two electrified locomotives and eight passenger railcars.

1.7. Personnel Information

1.7.1. Rail Gang Watchman

The rail gang watchman was hired by Amtrak in July 2017. He attended a 2-week new-hire

employee training program in Wilmington, Delaware, between July 31 and August 11, 2017. The

training program instructed new-hire employees on basic railroad safety rules and instructions,

including Amtrak-required safety training such as electrical safety near catenary tracks, initial

RWP training, training on Federal Railroad Administration (FRA) regulations, and bridge worker

safety.

The rail gang watchman completed his initial training on Northeast Operating Rules

Advisory Committee (NORAC) operating rules on October 31, 2017, and was requalified on

February 16, 2018. He was also requalified on RWP on February 17, 2018. He started Amtrak’s

initial watchman certification training program on November 6, 2017, completing the certification

training on November 15, 2017. He received his watchman qualification certification on

18

A catenary pole is an upright support pole that supports the weight of Amtrak’s overhead electrified system.

They are placed every 265 feet on the Northeast Corridor.

NTSB Railroad Accident Report

8

November 29, 2017. Testing records show that Amtrak conducted and documented 11 random,

unscheduled efficiency test examinations on safety rules for the rail gang watchman between

September 2017 and March 2018, and he passed all of them.

1.7.1.1. Sleep/Wake/Work Hours

The rail gang watchman was working Monday through Thursday between 6:00 a.m. and

4:30 p.m., with an unpaid 30-minute lunch break. The rail gang watchman had 3 consecutive

regular days off on Friday, Saturday, and Sunday, which he did not work. Table 1 shows his work

hours in the 8 days before the April 24 accident.

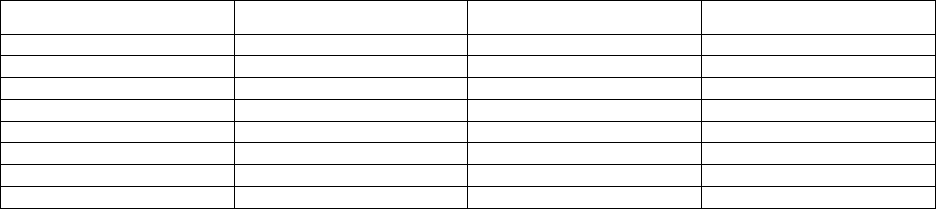

Table 1. Rail Gang Watchman work history hours.

Date Straight Time Hours Overtime Hours Total Hours

April 16, 2018

10.00

4.00

14.00

April 17, 2018

10.00

6.00

16.00

April 18, 2018

10.00

0

10.00

April 19, 2018

10.00

0

10.00

April 20, 2018

Day off

April 21, 2018

Day off

April 22, 2018

Day off

April 23, 2018

10.00

1.50

11.50

1.7.1.2. Postaccident Toxicology Testing

The FRA conducted postaccident toxicology testing on the rail gang watchman. The testing

screened for substances including amphetamines, barbiturates, benzodiazepines, cocaine, alcohol

and marijuana metabolites, methadone, methaqualone, MDA-analogues, opiates,

6-acetylmorphine, oxycodone, opiates, phencyclidine, and propoxyphene. The results were

negative for the presence of these drugs.

1.7.1.3. Cell Phone Usage

Forward-facing image recording from Amtrak train 86 revealed no evidence to suggest that

the rail gang watchman was talking on or using his cell phone or any other type of electronic device

when he was struck by the train.

1.7.2. Amtrak Train 86 Engineer

The engineer of Amtrak train 86 was hired in 2003 after previously working as an engineer

for CSX Transportation. A review of his training records shows that he was trained on specialized

Amtrak NORAC operating rules/Northeast Corridor special instructions and the characteristics of

the route and was certified as a passenger locomotive engineer under 49 CFR Part 240

“Qualification and Certification of Locomotive Engineers” regulations. Amtrak efficiency testing

NTSB Railroad Accident Report

9

records show that the engineer received both observational and written tests on April 19, 2018. He

successfully completed the on-track obstructions and restricted speed test sections.

19

1.7.2.1. Hours-of-Service

NTSB investigators reviewed about 2 months of the train engineer’s work history and

hours-of-service records to determine his compliance with the hours-of-service requirements in

49 CFR Part 228.

20

The engineer was regularly scheduled to work Monday through Friday, with

rest days on Saturday and Sunday, which he did not work. Table 2 shows his work hours in the

8 days before the April 24 accident.

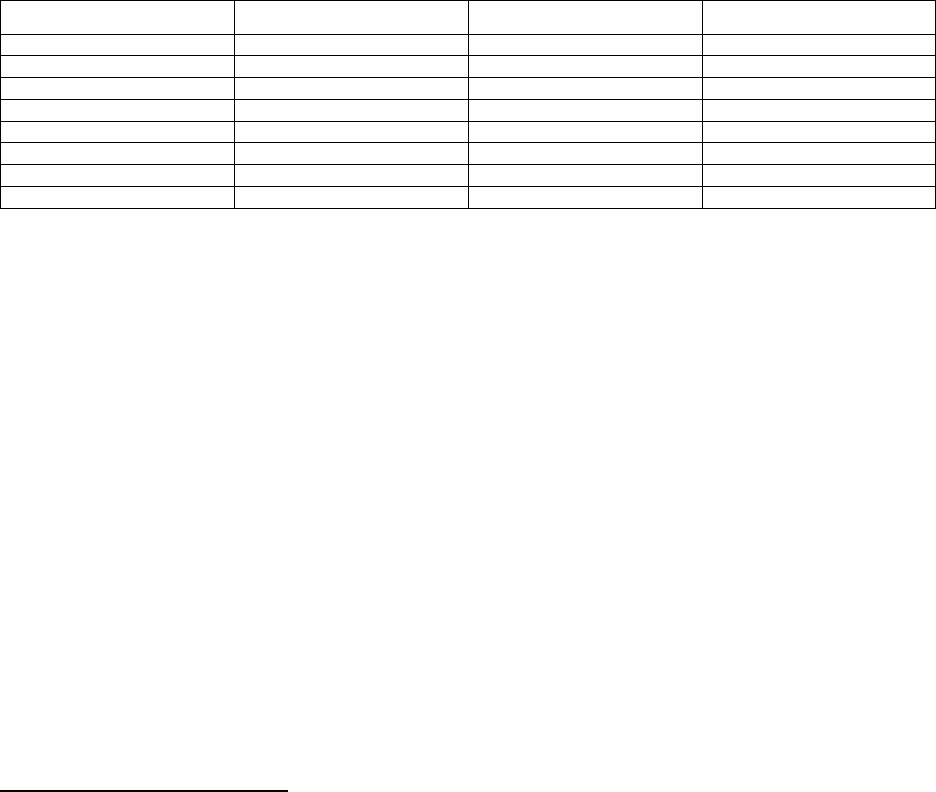

Table 2. Amtrak train 86 engineer work history hours.

Date Straight Time Hours Overtime Hours Total Hours

April 16, 2018

8.00

4.00

12.00

April 17, 2018

8.00

3.01

11.01

April 18, 2018

8.00

3.01

11.01

April 19, 2018

8.00

3.01

11.01

April 20, 2018

8.00

3.01

11.01

April 21, 2018

Day off

April 22, 2018

Day off

April 23, 2018

8.00

3.05

11.05

1.8. Roadway Worker Protection

FRA’s RWP regulation (49 CFR Part 214, Subpart C) requires railroads to have an on-track

safety program that includes rules, procedures, training, and equipment to be used to protect

roadway workers.

21

The rule states that railroads should develop and adopt procedures to protect

their roadway workers from being struck by trains and other on-track machinery. It also requires

the roadway workers to follow those rules and procedures to protect themselves and others.

Amtrak’s on-track safety program manual contained sections concerning on-track safety

protections, definitions, and procedures for implementation, which will be discussed later in this

report.

1.8.1. Amtrak Special Instructions

Although not mandated for use by Amtrak management, work zone speed restrictions are

an option RWICs can use for on-track safety. At the time of the accident, Amtrak Special

Instruction 175.S2 directed train dispatchers to issue an 80-mph slow-by speed restriction to trains

operating next to where roadway workers and track machinery were performing work. It also

directed train dispatchers to always slow trains as they passed by work zones where a track laying

19

Restricted speed is a method of operation that permits stopping within one-half the range of vision, and includes

specific provisions for controlling the movement, maintaining vigilance, and MAS. NORAC Rule 80 governs

movements made at restricted speed and requires that trains operate at speeds no greater than 20 mph while under

restricted speed.

20

Title 49 CFR 228.11 “Hours of Duty Records.”

21

Title 49 CFR 214.7 “Definitions” includes watchmen in the list of employees considered to be roadway workers.

NTSB Railroad Accident Report

10

machine or an undercutter were working on an out-of-service track. However, this instruction did

not automatically apply and had to be specifically requested by the RWIC. Although the speed

restriction was available for the work zone at the time of the accident and was mentioned in the

project’s SSSWP, it was not implemented.

22

1.8.2. Train Approach Warning

FRA regulations and FRA’s Track and Rail and Infrastructure Integrity Compliance

Manual, Volume 3, Chapter 3, require that roadway workers fouling track outside of working

limits be given warning of approaching trains by one or more watchmen (FRA 2018).

23

For TAW

protection to be effective, the warning must be given in sufficient time to allow each roadway

worker, including watchmen, to move to and occupy a previously arranged place of safety at least

15 seconds before the train’s arrival. The minimum 15-second warning time is calculated by using

the MAS of the trains operating through that location. Furthermore, the place of safety to be

occupied upon the approach of a train may not be on a track, unless working limits are established

on that track. The manual outlines specific requirements for watchmen and states that watchmen

must use distinctive and clear signals to all roadway workers, including other watchmen, warning

that a train or other on-track equipment is approaching. The watchmen assigned to provide TAW

are instructed to devote full attention to detecting the approach of trains and communicating a

warning and cannot be assigned any other duties while functioning as watchmen. The manual also

states that every roadway worker who is assigned the duties of a watchman must be trained,

qualified, and designated in writing by the employer to serve as a watchman in accordance with

the provisions in 49 CFR 214.349 “Training and Qualification of Watchmen/Lookouts.”

Furthermore, the manual states that the watchmen should communicate the warnings in a way that

can be detected by the roadway workers regardless of noise or work distractions, and that does not

require the roadway workers to be looking in one particular direction (FRA 2018).

1.8.3. Working Limits

Another form of on-track protection for roadway workers are working limits. According to

49 CFR 214.7 “Definitions,” working limits means a segment of track with definite boundaries

established upon which trains and engines may move only as authorized by the RWIC having

control over that defined segment of track. When the RWIC establishes working limits, the

authority to move trains is removed from the train dispatcher and granted to the roadway worker.

When working limits are established, the dispatcher makes an entry into the dispatching system to

show that segment of track is out of service, which activates the protections implemented by PTC

(see next section) or redundant signal protections. Working limits were not established for main

tracks 1 or 3 at the Bowie work zone; they were in place for main track 2 only.

1.8.4. Positive Train Control

The Rail Safety Improvement Act of 2008 mandated that all Class I and passenger railroads

fully implement PTC systems. That requirement was enacted nationwide on December 31, 2020;

22

For more information on the Bowie project’s SSSWP, see section 2.2.

23

Title 49 CFR 214.329 “Train Approach Warning Provided by Watchmen/Lookouts.”

NTSB Railroad Accident Report

11

however, this train and track were equipped with ACSES (a PTC system) before the date of this

accident. PTC is a technology-based system to prevent train accidents caused by human error,

including train-to-train collisions, overspeed derailments, incursions into established working

limits, and movements of trains through a switch left in the wrong position.

1.9. Postaccident Inspections

Amtrak train 86 was terminated at the accident site so that event and image recorder

downloads and mechanical inspections could be carried out. FRA motive power and equipment

inspectors performed a comprehensive inspection of Amtrak train 86. All mechanical systems were

inspected, including the braking system, horn, headlight, and auxiliary lights (ditch lights). FRA

test records were also reviewed. All systems inspected were found to be working as intended and

in compliance with federal regulations. Damage estimates and materials replacement costs for

Amtrak train 86 were estimated at $900.

An FRA signal and train control inspector examined the on-board cab signal system and

the ACSES PTC system on the lead locomotive for proper operation and compliance with FRA

regulations. The inspector also reviewed FRA-required test records. Both systems were working

as intended and in compliance with federal regulations.

Once the initial inspection of Amtrak train 86 was complete, it was released to return to

Washington, D.C.’s Ivy City Maintenance Facility for additional investigative and mechanical

compliance inspections by FRA and Amtrak investigators. The inspections and a review of

mechanical records indicated that no mechanical defects were found on the consist of Amtrak

train 86.

1.9.1. Sight Distance Observations

The NTSB performed sight distance observations in the area of the accident to determine

the struck watchman’s sight distance and warning time for trains approaching from the north on

main tracks 1 and 3, both in the position he was standing and at the bottom of the east ballast

shoulder, away from the track.

24

Where the rail gang watchman was standing on main track 1, he would have had a sight

distance of 4,770 feet looking north. For main track 1, this equates to about 30 seconds of warning

time for trains approaching from the north and operating at a MAS of 105 mph. For main track 3,

this equates to about 26 seconds of warning time for trains approaching from the north and

operating at a MAS of 125 mph. Because advance watchmen were located south of the rail gang

watchman and were responsible for alerting the rail gang watchman to trains approaching from the

south, the total warning time for the rail gang watchman for trains approaching from the south

would have been greater than that which his direct sight distance would have allowed; the total

warning time was greater than required by FRA regulations.

24

Title 49 CFR 214.329 “Train Approach Warning Provided by Watchmen/Lookouts” and Amtrak’s Roadway

Worker Protection Manual Rule 329.

NTSB Railroad Accident Report

12

The NTSB also estimated the rail gang watchman’s sight distance and warning time had

he been standing at the bottom of the east ballast shoulder by the access road and in line with the

catenary poles. When standing at this location and looking north, the left-hand curves and the

catenary poles on main track 1 obstructed the line-of-sight distances for both main tracks 1 and 3.

This reduced the sight distance to about 3,445 feet for main track 1, equating to about 22 seconds

of warning time for trains approaching from the north, operating at the MAS of 105 mph. For main

track 3, roadway workers would have had about 18 seconds of warning time for trains approaching

from the north.

1.10. Postaccident Actions

Amtrak made several changes to its work zone processes in response to this accident. These

actions include:

• Revised Special Instruction 175-S2 “80 mph slow-by” speed restriction to a “60 mph

slow-by” speed restriction for trains operating on tracks immediately adjacent to a track

laying machine or undercutter. These speed restrictions originally applied only to the

areas immediately adjacent to the track laying machine or undercutter, not the entire

work zone. The speed restriction now covers the entire work zone, rather than specific

locations of work equipment.

• Evaluated Amtrak safety risk management processes through working groups that

include management and field personnel. These groups identified the greatest risks in

work location and scope. Safety risks identified in this process include: RWP, exposure

to trains (both high speed and frequency), electrical hazards, and equipment collisions.

Safety risk findings are now being reported to Amtrak’s Executive Safety Council and

operating department heads.

• Revised and reintroduced the “Hot Spots” guide. The revisions included a sight

distance chart to aid roadway workers and watchmen in sight assessments when using

TAW. This manual was not provided to employees between 2014 and 2018. Amtrak

also included a job briefing requirement to guide employees in properly performing the

sight distance evaluation process. This information is now included in an SSSWP.

• Ordered additional portable aerial stands. Because it considers watchman aerial stands

useful to preventing accidents such as this one, Amtrak ordered more portable aerial

stands to supplement the 20 that it had in stock at the time of a December 19, 2019,

NTSB Record of Conversation between NTSB and Amtrak.

NTSB Railroad Accident Report

13

2. Analysis

2.1. Introduction

On April 24, 2018, about 8:58 a.m. local time, northbound Amtrak train 86 struck and

killed an Amtrak watchman in Bowie, Maryland. The train strike occurred on main track 1, about

1,500 feet north of the Bowie State Train Station on Amtrak’s Northeast Corridor. At the time of

the accident, the watchman was fouling the track while providing TAW to a group of rail welders

working on main track 2, the center track of a three-track territory. Working limits were established

on main track 2, which had been placed out of service under a continuous exclusive track outage

for maintenance on March 9, 2018. When the accident occurred, two trains were traveling in

opposite directions simultaneously through the work zone on main tracks 1 and 3.

This analysis discusses the accident and the following safety issues:

• Inadequate site safety risk assessment. (See section 2.2.)

• Unsafe train speeds in established work zones. (See section 2.3.)

• Ineffective roadway worker protection. (See section 2.4.)

Having completed a comprehensive review of the circumstances that led to the accident,

the investigation established that the following factors did not contribute to its cause:

• Mechanical condition of the train. FRA motive power and equipment inspectors

performed a comprehensive inspection on Amtrak train 86. The inspectors found that

all mechanical systems inspected, including the train’s braking system, horn, headlight,

and auxiliary lights, were working as intended and in compliance with federal

regulations.

• Train handling and warnings. A review of the event recorder data from Amtrak train 86

revealed that the engineer was operating the train at 99 mph, which was below the MAS

for main track 1 and that the engineer provided a series of five 1-5 second warning

blasts of his horn and bell between 8:57:40 a.m. and 8:58:10 a.m. to alert the roadway

workers as the train traversed through the work zone.

• Sight distance. NTSB investigators determined that the rail gang watchman’s sight

distance to detect approaching trains from the north was appropriate and consistent with

the minimum requirements outlined in 49 CFR 214.329 “Train Approach Warning

Provided by Watchmen/Lookouts.”

• Employee fatigue. The work/rest histories for both the rail gang watchman and the

engineer of Amtrak train 86 indicated that both employees had adequate opportunity

for rest in the days before the accident.

NTSB Railroad Accident Report

14

• Employee training. The training records for the rail gang watchman and the engineer

of Amtrak train 86 indicate that both employees were trained on Amtrak’s railroad

operating rules (NORAC) and all specialized training specific to their job.

• Impairment from drugs and alcohol. Postaccident toxicology testing on the rail gang

watchman were negative for drugs and alcohol.

• Cell phone use. Forward-facing image recording from Amtrak train 86 revealed no

evidence to suggest that the rail gang watchman was talking on or using his cell phone

or any other type of electronic device when he was struck by the train.

Thus, the NTSB concludes that none of the following were factors in the accident:

(1) mechanical condition of the train; (2) train handling and warnings from the engineer of Amtrak

train 86; (3) employee fatigue; (4) employee training; (5) watchman impairment from alcohol and

other tested-for drugs; and (6) cell phone usage.

2.2. Site-Specific Safety Work Plan

Forward-facing image recordings from Amtrak train 86 show that, in the moments before

he was struck by the train, the rail gang watchman was standing in the foul of main track 1 looking

toward the MARC train. According to the middle watchman, the rail gang watchman was standing

on the outside of the curved track on the ends of two crossties (a flat surface), just inches away

from the track.

The forward-facing image recordings from Amtrak train 86 appeared to indicate that the

rail gang watchman had a hood pulled up over his head and under his hardhat, which would have

impaired his hearing and possibly his range of vision. He was holding up an orange watchman’s

warning disc with his left hand and facing west in the direction of the southbound MARC train

that had entered the work zone on main track 3.

The rail gang watchman took a large risk when he assumed a position on the two crossties

on a live track. To understand why the rail gang watchman placed himself in the foul of a live

track, the NTSB interviewed four Amtrak employees who have worked as watchmen. Most of the

watchmen suggested that he likely stood on the crosstie ends for better stability, as the sloped

shoulder ballast along the east side of main track 1 was unstable and difficult to stand on. The

slope of the shoulder ballast along the west side of main track 1 was steep and consisted of loose,

slippery ballast, which created a tendency for the ballast to shift under the workers’ feet and caused

them to slide downhill. The NTSB notes that watchmen are expected to maintain one position for

extended periods of time and require safe and adequate footing to do so; the crossties provided

more stability than the steeply sloped ballast. Moreover, the rail gang watchman, when standing

on the crossties on main track 1, had a better view of the roadway workers on main track 2 and

trains approaching from the north on main tracks 1 and 3, compared with the view he had standing

on or at the bottom of the sloped wayside. Thus, the NTSB concludes that the rail gang watchman

was most likely standing on the crosstie ends to obtain stable footing and to improve the visibility

between himself and the roadway workers, as well as to improve his ability to see approaching

trains from the north.

NTSB Railroad Accident Report

15

Several roadway workers described the work site as noisy due to the construction work and

the equipment that was repairing the track. The workers also indicated that the MARC train crew

had activated the train’s horn and that several equipment operators had activated the horns on their

rail equipment. Additionally, as the southbound MARC train approached and passed through the

work zone from the north, the watchmen were providing approaching train warnings to the workers

for the MARC train.

The middle watchman positioned to the south of the rail gang watchman reported that he

could not hear the platform watchman’s horn when the Amtrak train was approaching. When he

detected the approaching Amtrak train and tried to get the attention of the rail gang watchman

using a handheld air horn, he could not attract the attention of the rail gang watchman, who

continued to look in the direction of the passing MARC train on main track 3. The noisy

environment necessitated the roadway workers to be vigilant and conduct visual scans to be alerted

to oncoming trains from both directions. The NTSB concludes that the rail gang watchman likely

did not realize that he was in imminent danger from northbound Amtrak train 86 because his

attention was focused on warning the rail gang of the southbound MARC train.

Before starting the project, Amtrak completed a SSSWP, a document intended to identify

existing or potential hazards and determine how best to eliminate, control, or minimize all

identified hazards to an acceptable level of risk. However, the SSSWP did not explicitly contain a

discussion of the safest forms of on-track protection for multiple-track environments, which the

NTSB believes is concerning given the critical role on-track safety has in protecting roadway

workers from being struck by a train. The SSSWP instructed roadway workers to follow RWP

rules; however, it did not provide instruction on how to safely comply with those rules. There was

no discussion in the SSSWP for this project on the speed of trains moving on adjacent tracks,

simultaneous train movements on adjacent tracks, or the unstable ballast conditions and the impact

of these on the watchmen’s ability to successfully perform their duties.

The SSSWP identified “on-track protection” as a hazard, but the instructions to control or

eliminate the hazard was simply to “comply with roadway worker protection rules and

procedures.” Amtrak’s safety risk assessment did not identify or define the specific hazards related

to on-track safety at this site. Moreover, the SSSWP failed to identify a safe and sufficient system

of on-track safety to adequately protect roadway workers from being struck by a train. For

example, the hazard assessment worksheet evaluated general safety topics, such as fall protection

and working in confined spaces, but contained little evaluation of the safety risks encountered

within the multiple track work zone, such as simultaneous train movements; steep ballast

shoulders; high noise levels; and trains operating at high speeds.

Amtrak’s SSSWP did not ensure that the locations where the watchmen would be working

were safe and effective. Given the multiple-track, high-speed environment, the position and safety

of the watchmen should have been a priority in the project safety planning. As discussed in

section 1.4, the term “hot spots” was used in the SSSWP, but it was not defined or adequately

explained, nor was additional information provided to workers in the 4 years before the accident.

Because “hot spots” identify locations where additional on-track safety is required, the term should

have been clearly defined in the SSSWP and remedies put in place to address the risks associated

with this hot spot.

NTSB Railroad Accident Report

16

The rail gang watchman was in an unsafe work position and was responsible for detecting

approaching trains moving in opposite directions on multiple tracks in a noisy environment.

Watchmen are critical in providing on-track protection, and the conditions under which they are

working must not hamper their ability to continuously sustain attention, perceive threats, process

information, and act. Watchmen are roadway workers and cannot properly protect others if they

are not properly protected themselves. The NTSB concludes that Amtrak’s SSSWP did not

consider all work zone hazards for roadway workers, including the watchmen, because it did not

identify the specific hazards relating to the multiple track work zone, such as simultaneous train

movements, steep ballast shoulders, high noise levels, and trains operating at high speeds.

Therefore, the NTSB recommends that Amtrak modify its SSSWP to require all work zone hazards

for roadway workers and watchmen be identified and mitigated, including hazards associated with

multiple main track work zones.

2.3. Train Speeds in Work Zones

At the time of the Bowie, Maryland, accident, trains were allowed to operate at MAS up to

125 mph on main track 3 and speeds up to 110 mph on main track 1. When Amtrak train 86 neared

the Bowie State Train Station, it was traveling northbound through the work zone on main track 1

at 99 mph, 6 mph below the posted 105 mph speed limit. The engineer placed the train in

emergency braking when he saw the rail gang watchman, which slowed the train to 98 mph. Had

Amtrak train 86 been operating at restricted speed (no greater than 20 mph) through the entire

work zone, the rail gang watchman would have had significantly more time (50 seconds) to detect

the signal from the watchman to the south that there was an oncoming train and move to a place

of safety. Moreover, under NORAC Rule 80, restricted speed requires engineers to operate at a

speed where they can be prepared to stop in advance of an obstruction on the track. Thus, the

Amtrak engineer would have been able to bring the train to a safe stop upon observing the rail

gang watchman fouling the track.

The SSSWP Amtrak produced prior to the Bowie accident was inadequate and did not

identify and mitigate all anticipated risks, such as the speeds of the trains, as noted above. The

NTSB found in its investigation of an April 3, 2016, collision of an Amtrak train with

maintenance-of-way workers and equipment in Chester, Pennsylvania, that Amtrak did not prepare

a SSSWP before the initiation of that project and concluded that had Amtrak instructed dispatchers

to operate trains at significantly slower speeds through the Chester work zone, the severity of the

accident would have been diminished (NTSB 2017). As a result, on December 28, 2017, the NTSB

issued Safety Recommendation R-17-23 to Amtrak.

Conduct a risk assessment for all engineering projects and use the results to issue

significant speed restrictions for trains passing any engineering project that

involves safety risks for workers, equipment, or the traveling public, such as ballast

vacuuming, as part of a risk-mitigation policy. (R-17-23)

Safety Recommendation R-17-23 is on the NTSB’s 2021-2022 Most Wanted List of

Transportation Safety Improvements in the issue area “Improve Rail Worker Safety.”

In response to this recommendation, effective June 25, 2018, Amtrak expanded existing

special instructions regarding speed restrictions for specific situations in work zones to include a

NTSB Railroad Accident Report

17

speed reduction to 60 mph past a continuous and planned track outage when undercutters or track

laying machines were being used. Amtrak also contracted with an engineering firm to conduct a

risk assessment and evaluate its TAW procedures. On August 13, 2019, the engineering firm’s

study identified safety enhancements for all of Amtrak’s maintenance-of-way activities, which

Amtrak adopted. Among these enhancements, TAW works zones were addressed with a

slow-order process that decreased train speeds entering TAW work zones from 80 mph to no

greater than 60 mph, which also allowed for a lower speed restriction in higher-risk locations.

On February 19, 2020, the NTSB replied to the FRA that a risk assessment of TAW speed

restrictions must consider sight distances and the resulting warning time for work crews and that

our review of Amtrak’s risk assessment and evaluation of its TAW procedures did not find any

analysis of available sight distances and resulting warning times for work crews nor any guidance

for how to determine when a lower slow-by speed is needed.

On August 23, 2020, Amtrak replied that reductions in speed below 60 mph allow a

minimum of 15 seconds between when a train is first sighted and when it reaches the work site, as

mandated by the FRA in 49 CFR 214.329. On May 13, 2021, the NTSB replied that the sight

distance calculations did not appear to include time for factors such as mental processing and a

worker navigating terrain before reaching the preplanned position of safety. The NTSB also said

that the reduction of train speed from 80 mph to 60 mph was insufficient and that it was imperative

to further reduce train speed as well as provide additional watchmen/lookouts to ensure the safety

of roadway workers. The NTSB asked Amtrak to revise its risk assessment guidance for

higher-risk work areas to mandate significantly slower train speeds than 60 mph. Safety

Recommendation R-17-23, remained classified “Open—Acceptable Response.”

Although reducing the speed to 60 mph would have resulted in an additional 7 seconds of

warning time for the watchman, the NTSB is concerned that this speed reduction may still not

allow enough time for roadway workers to be alerted to an oncoming train, process the

information, and navigate terrain to reach a place of safety before the approaching train arrives at

the roadway worker’s location. This is particularly true in higher-risk areas such as the Bowie

work zone where simultaneous train movements, steep ballast shoulders, and high noise levels are

present. The NTSB concludes that had Amtrak required trains to approach at significantly lower

speeds through the Bowie work zone, the rail gang watchman would have had more time to become

aware of the approaching train and relocate to a place of safety. Although Amtrak produced a

SSSWP for the Bowie project, it did not identify the need for reduced speeds, which would have

provided additional safety benefits through the work zone. The NTSB believes that the

circumstances of the accident in Bowie support the need for risk assessments that include

significant speed restrictions, as recommended in Safety Recommendation R-17-23. Therefore,

the NTSB reiterates Safety Recommendation R-17-23.

2.4. Roadway Worker Protection

Title 49 CFR 214.7 “Definitions” defines TAW as “a method of establishing on-track

safety by warning roadway workers of the approach of trains in ample time for them to move to

or remain in a place of safety.” TAW relies critically upon watchmen to detect, recognize, and

announce the approach of trains into the work site. In this accident, the rail gang watchman did not

NTSB Railroad Accident Report

18

detect the approach of the train, thus, the use of TAW did not provide sufficient on-track

protection.

The effectiveness of TAW is predicated on human performance and rules compliance and

relies on administrative controls. Multiple factors, including a noisy, challenging physical

environment and high train speeds with multiple trains transiting the area from opposite directions,

made TAW an ineffective choice for on-track safety protection. Prior NTSB reports identify that

the use of TAW did not protect roadway workers, and this accident further demonstrates the

failures of TAW (NTSB 2009, 2018, 2020). Title 49 CFR 214.329(e) states that

“Watchmen/lookouts shall communicate train approach warnings by a means that does not require

a warned employee to be looking in any particular direction at the time of the warning, and that

can be detected by the warned employee regardless of noise or distraction of work.” This portion

of the TAW regulation was clearly not met in this accident because of the multiple tracks and a

high-noise environment.

In the NTSB’s investigation of a June 10, 2017, accident in Queens Village, New York, in

which the foreman of a work crew for the Long Island Rail Road was killed when he stepped into

the path of an oncoming train, the NTSB found that “train approach warning regulations do not

ensure protection for roadway workers to inspect and work on tracks where trains are allowed to

continue to operate (NTSB 2020).”

25

As a result of the Queens Village accident investigation, on

May 14, 2020, the NTSB issued Safety Recommendation R-20-6 to the FRA.

Define when the risks associated with using train approach warning are

unacceptable and revise Title 49 Code of Federal Regulations 214.329 to prohibit

the use of train approach warning when the defined risks are unacceptable. (R-20-6)

This recommendation applies to all uses of TAW in all territories and is on the NTSB’s

2021-2022 Most Wanted List of Transportation Safety Improvements in the issue area “Improve

Rail Worker Safety.”

On April 21, 2021, the FRA replied that it disagreed with R-20-6. The FRA stated that the

findings from the Queens Village accident, which were the basis for this recommendation, were

faulty. The FRA said that roadway workers involved in the Queens Village accident did not comply

with basic requirements of FRA regulations governing TAW because they failed to occupy or even

discuss a predetermined place of safety from oncoming trains. Therefore, the FRA stated that it

believed that these failures were the cause of the accident, not the decision to use TAW. The Bowie

accident clearly illustrates the risks associated with using TAW in controlled track territory.

Amtrak did not consider these various risks when they established TAW for the work zone, which