A Best Practices Manual for Using

Compressed Earth Blocks in Sustainable

Home Construction in Indian Country

U.S. Department of Housing and Urban Development | Office of Policy Development and Research

A Best Practices Manual for Using Compressed Earth Blocks in

Sustainable Home Construction in Indian Country

Prepared for

U.S. Department of Housing and Urban Development

Office of Policy, Development and Research

Prepared by

Thomas Bowen

University of Colorado, Boulder

May 2017

ii

Acknowledgments

The author thanks Mike Blanford at the U.S. Department of Housing and Urban Development,

Office of Policy Development and Research for the opportunity to contribute to the necessary

and expanding collection of information available to aid tribes in alleviating their troubling

housing circumstances. Mike was also instrumental in providing direct assistance with review

and editing of this manual’s contents, while maintaining a steady and encouraging demeanor.

The author also thanks JoAnn Silverstein and Rob Pyatt at the University of Colorado and the

native people of North America.

Disclaimer

The contents of this report are the views of the contractor and do not necessarily reflect the views

or policies of the U.S. Department of Housing and Urban Development or the U.S. government.

iii

Preface

Introducing innovative building products and processes is an important endeavor in all

communities. Combining that with the incorporation of housing sustainability, culturally relevant

values, and tribal collaboration with builders in Native American communities was the overall

goal of this project. The development and use of compressed earth blocks in the construction of

Indian housing provided an alternative to conventional construction materials and methods, and

provided culturally relevant materials to address community values for tradition.

This work was funded through a grant from the U.S. Department of Housing and Urban

Development (HUD), Office of Policy Development and Research. In recent years, HUD, along

with other federal agencies, has employed various approaches to provide resources and engage

tribes in community-driven solutions to address Native American housing issues. Innovative

building products aimed to be relevant to cultural values, on the one hand, may challenge the

traditions and cultural practices historically employed by the tribes’ housing leadership but can

also provide an opportunity to develop a construction process with increased resident

participation and communitywide engagement often associated with economic benefits for the

tribe.

This manual provides examples of community-driven processes used to incorporate traditional

tribal values while addressing both the immediate and future housing needs of tribal residents

and their neighbors. The manual demonstrates the use of compressed earth blocks as a local,

largely ubiquitous, and tribally manufactured resource for achieving quality, healthy, and

affordable housing, while also advancing the parallel goals of self-sufficiency, sustainability,

and energy independence.

iv

Contents

Historical Context ............................................................................................................................1

Mission and Vision ..........................................................................................................................2

Strategy ............................................................................................................................................5

Tactics and Logistics ........................................................................................................................6

Developing the Soil Resource ..........................................................................................................6

Technical Support and Funding .......................................................................................................9

Soil Testing ..................................................................................................................................9

Excavation and Hauling of Soil .................................................................................................10

Production of CEBs .......................................................................................................................12

The Crew ....................................................................................................................................12

Production Site ...........................................................................................................................13

Equipment ..................................................................................................................................14

CEB Curing and Inventory Control ...........................................................................................16

Design and Construction ........................................................................................................................ 18

Design Considerations for Building With CEBs ...........................................................................18

Overview of the CEB Construction Practice .................................................................................20

Foundation ..................................................................................................................................20

Building Up the Walls ................................................................................................................21

General Business Guidelines ........................................................................................................25

References ......................................................................................................................................26

Appendix ........................................................................................................................................27

v

List of Figures

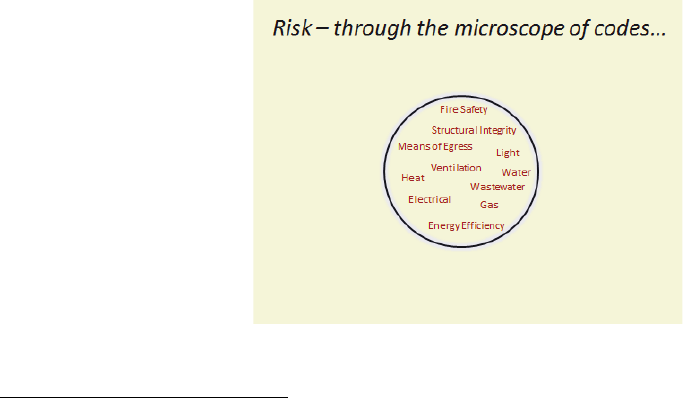

Figure 1. The Risks to Human Life Captured by Current Building Codes ............................................ 3

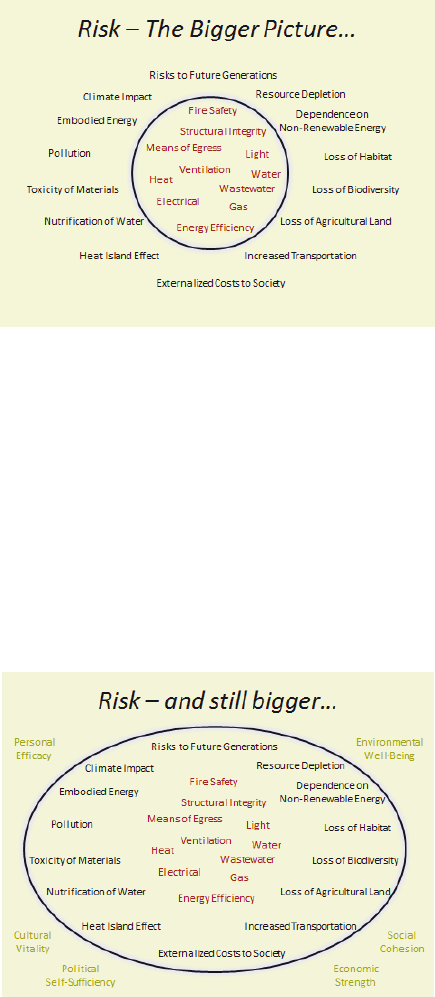

Figure 2. Risks That Eisenberg Contends Should Be Incorporated Into Building Codes ...................... 4

Figure 3. Pinoleville Pomo Nation Identified Additional Risks Absent Current Codes ........................ 4

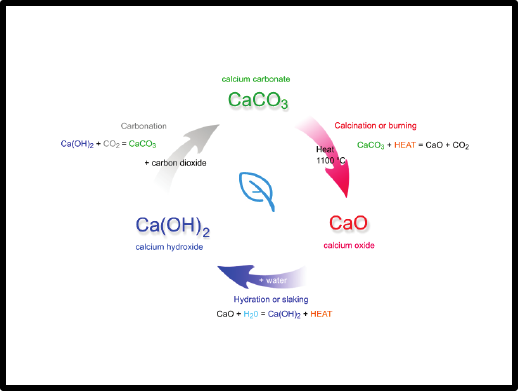

Figure 4. The Hydrated Lime Cycle ........................................................................................................ 8

Figure 5. Truck and Pup ......................................................................................................................... 11

Figure 6. Advanced Earthen Construction Technologies (AECT) MX20 CEB Mixer ....................... 15

Figure 7. AECT 3500 CEB Machine ..................................................................................................... 16

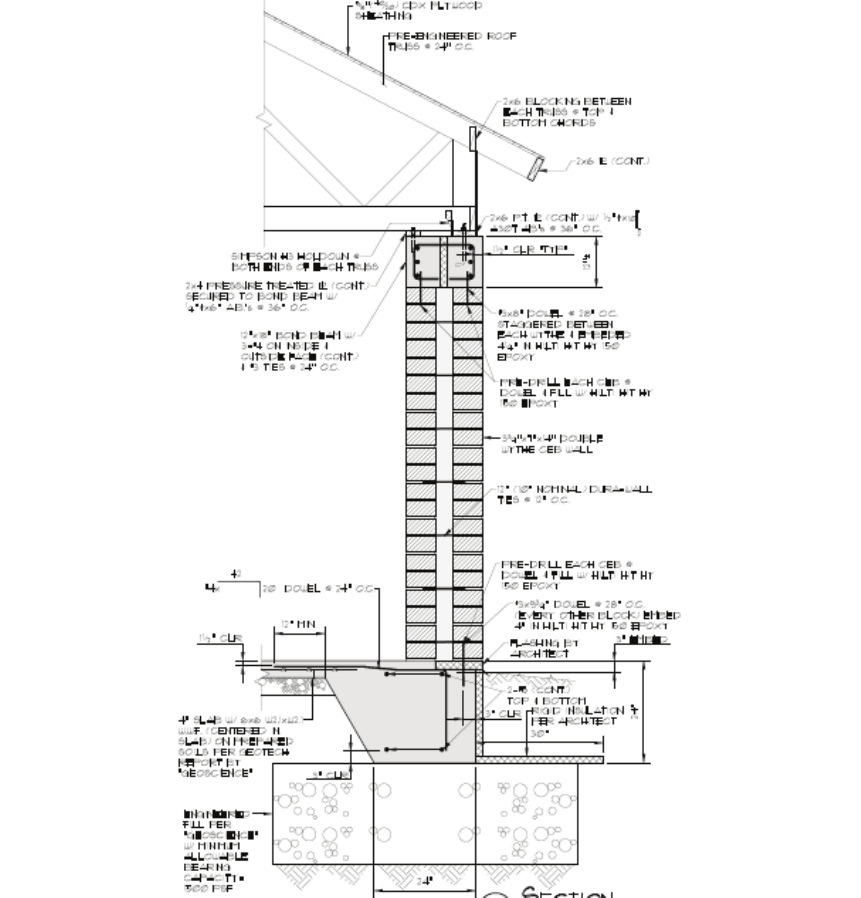

Figure 8. Showing Double Wythe Wall Diagram With Insulation Chase ............................................ 19

Figure 9. Overexcavated, Compacted, Filled, and Shaped Subfoundation .......................................... 20

Figure 10. Window Bucks Installed ....................................................................................................... 22

Figure 11. Orange Story Pole at Corner Bolted and Braced to Foundation ......................................... 23

Figure 12. Finished Bond Beam With Shed Roof Framing .................................................................. 24

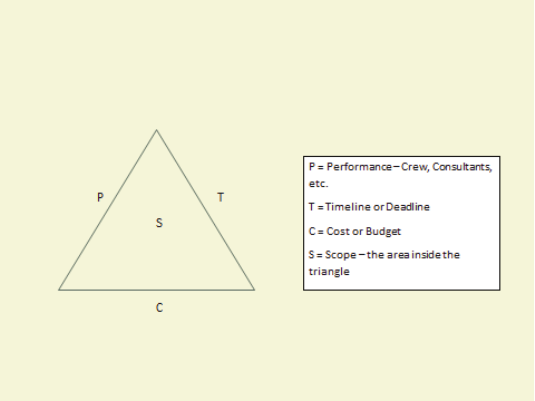

Figure G-1. Scope (PTC) Triangle Showing Dependent Linkage of Project Management Factors ... 38

1

Historical Context

Compressed earth blocks (CEBs) are a natural infusion of modern technology with one of the

earliest elements of manmade structures: the mud brick or adobe block. CEBs are essentially

molded adobe blocks produced using mechanical compaction. Shaped and compacted earth was

used as early as 8300 B.C. as a construction material for the ancient city of Jericho, near what is

now Jordan.

1

Taos Pueblo in northern New Mexico is the largest surviving multistoried adobe

structure and the oldest continuously inhabited adobe site in the United States.

Historical construction practices, as with these two examples, were to use the best materials that

were available close at hand. People built their own homes as efficiently as possible.

Transporting substantial construction materials long distances or relying on sophisticated tools to

manipulate these materials was not practical. Earth or dirt, is both abundant and easily

manipulated into suitable structures. Current construction techniques and building materials

show little resemblance to those ancient practices. Nowadays, building products are often either

harvested elsewhere and trucked in from long distances or manufactured from materials that

would have been unrecognizable to our ancestors. “Technological advancements” remove the

local influence on what and how to build while adding significant costs to the bottom line of

projects. Developers, who build most houses today, maximize their profits by using and reusing

designs similar to one another and purchasing building materials in huge quantities. The new

building process has eliminated much of the regional diversity in housing types that had been

borne of a healthy reliance on locally abundant natural materials and designs that uniquely

equipped structures to respond to regional climate and other environmental influences.

Unfortunately for tribes, the drastic changes in housing production in the United States coincided

with increasing federal efforts to standardize housing across the tribal reservation system. During

the 1960s and 1970s, the U.S. Department of Housing and Urban Development (HUD)

sponsored a housing construction boom in Indian Country moving many tribal members into

culturally irrelevant subdivisions of carbon-copy tract homes. By 1996, the federal government

had criticized the outcome of their effort in a study.

2

In response, Congress authorized HUD to administer and provide housing assistance to Native

American tribes through a block grant program under the Native American Housing

Assistance and Self Determination Act of 1996 (NAHASDA).

3

This drastically changed how

housing was created and managed in Indian Country, with HUD now providing tribes with the

necessary funding and the tribes determining the means and methods of providing housing for

their members. Using NAHASDA and its subsequent amendments, tribes are able to consider

alternatives to conventional construction methods and respond to culturally relevant

community-driven needs and values in their own traditional and historic ways. In the years

since NAHASDA went into effect, the partnership between HUD and Native American

housing authorities has been strengthened, due to many successes at the tribal level and grant

1

http://www.astm.org/Standards/E2392.htm.

2

http://www.gpo.gov/fdsys/pkg/GAOREPORTS-T-RCED-97-105/pdf/GAOREPORTS-T-RCED-97-105.pdf.

3

http://www.portal.hud.gov/hudportal/HUD?src=/program_offices/public_indian_housing/ih/codetalk/nahasda.

2

allocations to tribes. In 2014, Indian Housing Block Grants (IHBGs) and Indian Community

Development Block Grants (ICDBGs) combined for more than $725 million of assistance.

4

HUD is also expanding opportunities for tribes by actively partnering with other federal agencies

on behalf of tribal housing interests. In 2014, HUD’s Office of Native American Programs

collaborated with the Bureau of Indian Affairs (BIA), the Indian Health Service, the U.S.

Departments of Agriculture and Energy, the Federal Emergency Management Agency, and the

Environmental Protection Agency to promote healthy, sustainable solutions for the housing

issues in Indian Country.

5

The changes in how federal agencies interact with tribes offer tribes

the opportunity to explore the best options in housing design and construction and develop their

own housing programs. Such programs can expand the self-sufficiency and sustainability of the

tribes while honoring the unique values and cultural traditions that secure their identity.

This manual is a product of HUD’s Sustainable Construction in Indian Country Small Grant

Program and presents information and guidance for the production, design, and construction use

of CEBs as a viable solution for the long-term housing needs on Native American reservations. It

is intended for tribal organizations familiar with home construction on reservations, but less

familiar with the process of creating a tribally run home construction enterprise. It advocates

sustainable construction practices that leverage the benefits of available local resources and labor

while inviting broad community participation in the process.

Mission and Vision

Sustainable building practice requires the consideration of factors that go beyond the traditional

meanings of safe and healthy construction. Such an approach demands a commitment to

internalizing the intended and unintended effects of a construction project and using them to

inform the decisionmaking process for what, where, and how to build. First, however, builders

should address the question of why to build by enlisting the input of the community and

discussing the specific influence that home construction projects can have on the local economy,

infrastructure, transportation, and surrounding area. Incorporating the opinions of the whole

community ensures that the project can reflect the culture, tradition, norms, and values that are

the core of the tribe’s identity. The outcome of this effort should yield more than just a home

design—that work comes at a later time. The output of guiding principles, standards, and codes

will govern the way in which homes are designed and constructed and should speak to the ideals

that preserve the integrity and values of the tribe.

Tribes are uniquely positioned to leverage their sovereignty to develop building codes that are

more reflective of who they are and what they wish to become, while integrating consideration

for current and future residents and their neighbors. Tribes, through a sustainable housing

project, can seize the opportunity to address the larger issues that are at the core of many of their

population’s struggles. Whether the inherent issues are underemployment because of lack of

4

$650 million for IHBG and $77 million for ICDBG grants in 2014. See

http://www.portal.hud.gov/hudportal/documents/huddoc?id=NAHSINGBLOCKGRANTS.pdf and

http://www.portal.hud.gov/hudportal/HUD?src=/program_offices/administration/grants/fundsavail/nofa14/icdbg.

5

http://www.portal.hud.gov/hudportal/documents/huddoc?id=NAHSINGBLOCKGRANTS.pdf.

3

industry, a population scattered across a large reservation, or a combination of influences not yet

defined, the reality is that the imperative and solutions to correct the housing problem in Indian

Country rest with the tribes rather than with the agencies that dispense federal funds.

In 2011, the Pinoleville Pomo Nation (PPN) partnered with the Developmental Center for

Appropriate Technology (DCAT) to create their own building code by rewriting existing

building codes. PPN enacted a community-oriented review process to engage the broadest

possible representation of tribal values. An excerpt from the draft reveals a strong emphasis on a

pragmatic interpretation of sustainability:

This approach is an effort for the tribe to create its own standards that permit the highest

degree of design freedom, while also protecting health, safety and well-being of its

multiple constituencies: current residents and neighbors, to be sure, but also future

generations of people and nonhumans that share local ecosystems with us. We realize that

tensions may arise between the comfort and security of present residents and our

commitment to leaving a healthy and sustaining world to future generations of people and

nonhumans. We embrace these tensions and seek ways to balance fairly the burdens and

opportunities associated with design choices. We also believe many design elements—

old and new—can reduce the tension to near zero. That is, we can have safe, healthy,

environmentally sustainable, culturally appealing buildings now and preserve the same

opportunity for future generations, if we design thoughtfully.

6

DCAT is a nonprofit organization based in Tucson, Arizona dedicated, in short, to promoting

sustainable construction. In 2010, DCAT Director David Eisenberg gave a presentation

highlighting the limited scope of current building codes at an International Code Council

workshop in Boston, Massachusetts.

7

The images that follow, shown as figures 1 and 2, are

drawn from the material in that presentation.

Figure 1. The Risks to Human Life Captured by Current Building Codes

6

http://www.epa.gov/region9/greenbuilding/codes/pdfs/pinoleville-green-building-code-draft.pdf.

7

http://www.dcat.net/about_dcat/announcements.php.

4

Figure 2. Risks That Eisenberg Contends Should Be Incorporated Into Building Codes

These representations illustrate the disconnect between the risks managed by currently accepted

building codes, like the Uniform Building Code (UBC) and International Residential Code

(IRC), and the larger, externalized, and hidden risks inherent in typical construction practices. As

Eisenberg relates it, the first image depicts all the risks the building may pose to the occupants

and others nearby. The current building codes are designed to mitigate these risks. The second

image (figure 2) illustrates the impacts the building has on the larger community, the

environment, and future generations that current codes do not cover. The PPN added to the

image by including aspects of their tribe’s welfare that were put at risk by the limitations of

current codes, shown in green in figure 3.

Figure 3. Pinoleville Pomo Nation Identified Additional Risks Absent Current Codes

How does this concept fit within a vision of a self-sustaining tribal construction enterprise? Until

very recently, the IRC or UBC did not include CEBs and other earthen building materials (such as

straw bale and cob) and techniques. These construction materials and methods, however, are

perfectly capable not only of meeting or exceeding those codes, but (more importantly) any possible

codes that could be implemented to incorporate the broader risks identified in figures 2 and 3. For

many years, tribes either received or were forced to construct houses conforming to conventional

building codes (for example, UBC and IRC.). More recently, the urgent need for shelter, coupled

with limited funding, has manifested in a pick-and-choose approach to the application of building

5

codes on reservations. This approach has not resulted in better quality homes. Resulting structures

often have reduced functionality, present a higher risk to the occupants, and deteriorate at an

accelerated rate. Fortunately, major code authorities, like the New Mexico Earthen Building

Materials Code,

8

have now adopted standards for earthen construction practice, and many architects

and engineers are familiar with the appropriate design requirements that facilitate speedy code

approval and a smooth construction schedule. Before undertaking the creation of a housing

construction entity or just contracting for home building services, the tribe will better serve its long-

term interests by contemplating how such efforts fit into the vision of their future and how choices

made today could sustain them.

9

Strategy

More directly, you should focus your early strategy on identifying the list of specific project

deliverables within the scope and assessing your internal capacity to meet them. Any and all gaps

can be met by renting expertise. For any housing project, you will need design and engineering

expertise, project management, and the usual construction trades, such as excavation,

framing/masonry, electrical, and plumbing. Hiring the competency within your tribe is the best

solution. Absent that opportunity, you can leverage contracting services from outside to further

support the tribe through an apprenticeship or internship agreement with the suppliers of these

services; however, outsourcing should only be a temporary solution. You can incentivize

contractor cooperation with any mentorship program through reduced Tribal Employment Rights

Ordinance fees or by citing it as a hiring preference within the procurement process. The entire

process is intended to require less specialization and technology than other building practices

(because the focus is particularly on using CEBs) and is therefore more conducive to experiential

(on-the-job) learning and training.

When starting a new CEB housing project, it is important to follow a manageable strategy,

working on one house at a time. It is ill-advised to seek initial funding to build 8 or 10 CEB

houses before you have built 1. This concept relates to the part on measuring success. The

project sponsor will measure your success on how many of homes you have completed, though

you might measure your success on a more intrinsic level. For example, you might feel

successful having just figured out the optimal crew composition during construction on your

third house.

I advise completing one CEB house before starting or even anticipating another. Then you

should assess how much that first house really cost, how long it actually took, which design and

field modifications you will keep, which contractors you will retain, and what else you would

change for the future. The next project will need a new plan that incorporates the knowledge

gained from reviewing the first.

8

http://164.64.110.239/nmac/parts/title14/14.007.0004.htm.

9

http://www.epa.gov/Region9/greenbuilding/codes/pdfs/tribal-green-building-code-template-draft-admin-code.pdf.

6

Tactics and Logistics

When building with CEBs, clear advantages exist to also producing the CEBs as part of a cost-

reduction, benefit-enhancement approach. The tribally produced CEBs could then be sold to the

tribal construction entity (provided tribes follow federal procurement rules if using those funds).

In such a case, it would be necessary to separate the CEB production and CEB construction

entities operationally and fiscally, while also ensuring that pricing is reasonable and negotiated

ethically and transparently. The following list contains many of the benefits to producing and

building with CEBs simultaneously.

• The main ingredients of CEBs—sand and clayey soil—are often readily available on or

near your project site, significantly reducing transportation costs.

• You have control of the supply of raw materials and the manufactured CEB products.

• Sand and soil are nontoxic elements, which produce healthier homes.

• CEBs are mold, insect, fire, and rodent resistant, unlike hollow-wall constructed homes.

• CEBs have a low rate of thermal conductivity, meaning they are generally warmer in the

winter and cooler in the summer, reducing the energy needed to control the indoor

temperature.

• CEB houses are sturdier and lower maintenance than most other homes, which is also

true compared with adobe homes. The uniform compaction and dimension of CEBs

improves durability and flexibility of use over adobe blocks.

• CEBs are generally more energy efficient to manufacture than cement-based concrete

materials.

• Construction with CEBs requires minimal skill and few tools, and masonry is an ancient

and relatively common building technique; this makes CEB construction suited for do-it-

yourself builders and self-help construction projects.

• Producing CEBs creates local jobs and increases money circulation on the reservation.

Walls are one of the most expensive parts of the home, accounting for 20 percent or more

of the total home cost.

10

Insourcing critical infrastructure builds capacity and spurs

additional economic growth.

• These economic and environmental sustainability advantages make CEB projects more

attractive for funding agencies to sponsor.

Developing the Soil Resource

Typically, workers form CEBs by combining angular sand aggregate (40 to 70 percent), clay soil

(15 to 60 percent), and water (8 to 12 percent). They then mix the dry components, add water,

and thoroughly remix before putting the contents into a mold. Workers then compressed the

mold either manually or hydraulically to form a block. In wetter climates, adding a mix

proportion of cement of lime at 4 to 6 percent stabilizes the CEBs; adding Portland cement or

hydrated lime reduces the capacity of the CEBs to absorb moisture, which in turn reduces their

vulnerability to deterioration (Minke, 2000).

10

http://www.nahb.org/generic.aspx?genericContentID=169974.

7

The internal mechanics of the block, without going into too much technical detail, rely on the

binding performance of the clay for the form and structural integrity of the block. Structural

integrity is not to be confused with the strength of the block—sand largely provides the CEB’s

strength. The grains of the two different materials, each of varying sizes, mixed to a wet (damp,

not dripping) oatmeal consistency cling together in a slightly sticky bond. This mix is essentially

the same as adobe. Compression at 1,200 psi or so in a mold shapes the block and tightens the

interior binding between the clay and sand grains at a microscopic level—this turns adobe into a

CEB. The CEB cures in a moist climate for 28 days (to encourage a more gradual rate), allowing

the excess water from the original mix to evaporate, which leaves behind tiny air pockets.

In dry climates (with low relative humidity or minimal rain or snowfall), unstabilized CEBs will

likely perform well with minimal regular maintenance, required at roughly the same frequency as

house painting. In more humid or frequently wet climates, these same blocks will absorb surface

and ambient moisture. This will cause the block to swell slightly (it is a good general rule to

assume all clay swells) and subsequently shrink upon drying, potentially increasing the size of the

voids in the block. Repeated often enough, the pattern will eventually lead to cracking, spalling,

and deterioration of the block and the building structure. In the case of a wetter climate, stabilizing

the blocks with lime or cement is mandatory. At 4 to 6 percent by weight, the added hydrated lime,

for example, initiates a chemical reaction with the clay and water that significantly reduces the

short- and long-term moisture absorbing and retention capacity of the soil. With stabilized CEBs

(SCEBs) it is very important to slow the curing process by maintaining a moist environment, either

in a controlled climate space or by misting them with water multiple times daily and keeping them

covered with waterproof material. The stabilization process may produce CEBs that work even

with highly expansive clays. You will need to include hydrated lime in selection of the soil, but the

increased durability of the CEBs should balance the cost.

Cement is a popular choice for the stabilization of clay soils, particularly in the United States

where lime is less familiar to the building trades, and as such, is not as readily available.

Unfortunately, cement production (actually its precursor, clinker) is responsible for significant

global carbon dioxide (CO

2

) emissions, and therefore, is not considered an environmentally

sustainable product.

Alternatively, hydrated lime, while emitting CO

2

during the burning phase of its production,

reabsorbs equivalent amounts of CO

2

from the atmosphere during carbonation, resulting in a

carbon-neutral lifecycle. Figure 4 depicts the typical hydrated lime cycle process.

11

11

http://www.naturalhydrauliclime.com/customer/main/what_is_lime.php?display=what_is_lime.

8

Figure 4. The Hydrated Lime Cycle

Sand and clayey soils are generally abundant throughout the United States. The tribal offices of

natural and cultural resources may have information on locating a sufficient resource of these

materials on the reservation. Some sites may be off-limits for historic preservation or other

reasons. When determining locations for preliminary soil sampling, I advise considering the

proximity to roads suitable for transporting frequent heavy loads (avoid hospital and school

zones and high traffic areas) and proximity to active floodplains for the obvious reasons, but also

because these areas tend to have high levels of silty soil and organic materials that are not

suitable for CEBs. When you have a choice of location for your mining operation, consider

aesthetics, possible impact to neighbors, and future use or value of the site. From an economic

perspective, locating the mine site close to your CEB production facility could save substantial

transportation costs. It may be important to consider the color of the local clay for the CEBs you

plan to use in your project. The list of variables influencing selection of a primary site warrants

multiple sampling sites, and it is necessary to have a costly closure and reclamation plan for each

potential site. A minimum of five initial soil sample locations is advised.

It is possible to make CEBs at the construction site. Proximal production would save

significant transport costs, but depending on the size of the project and site, it may also have

disadvantages. The footprint for a block-making operation, even on a single house scale, is

substantial. Depending on the design, a 1,200-square-foot house can require 4,500 to 5,000

CEBs, 90 cubic yards of material (clay and sand), storage and handling space, plus mixing

space, block-making space, and a manufactured CEB curing area (60 to 90 pallets depending

on pallet quality). The soil excavated for the house’s foundation may be suitable for CEB

production, which strengthens the argument for onsite manufacture. Consider other factors

like shelter from weather so the mix does not get wet, possible delays in other onsite

construction because of limited space, security fencing of the production yard, and

reclamation of the production and soil “mining” area if the soil is not from the foundation.

Give due attention to quality and inventory control. Deviation from proper mix ratios to

“stretch” the available quantities further, due to limits to the volume of site-based material, is

ill advised. This warning is not intended to discourage onsite production of CEBs, but to

9

serve as a guide when considering the various factors and to avoid reducing the overall

feasibility of the block-making approach selected and the progress of the home-building

project.

Technical Support and Funding

Using a skilled geologist to study maps of the reservation’s geography and topography and

previous studies or current large-scale excavation work saves significant time and money.

Fortunately, tribes already have a federal partner that will provide preliminary site identification

and initial soil classification at no cost.

The Division of Energy and Mineral Development (DEMD), based in Denver, Colorado, is a

specialty branch of the office of the U.S. Assistant Secretary of Indian Affairs.

12

DEMD’s

mission is to assist tribes with development of their mineral and energy resources by providing

evaluation, business planning, and marketing expertise to advance tribal goals. More specifically

related to CEBs, DEMD offers the use of experienced geologists to locate the clay and sand

resources on reservations and provides estimates on extraction costs and mining plans for further

development. In addition to these free services, DEMD offers a broader project development

funding opportunity through its Energy and Mineral Development Program (EMDP) grant.

DEMD experts will assist the tribes in attaining these funds to develop clay and sand resources to

sustain long-term production of CEBs. The EMDP is relatively straightforward; many of the

technical justifications are usually detailed in the preliminary mineral study provided by DEMD.

As a direct technical resource for mineral, oil and gas, and alternative energy exploration,

DEMD personnel are both familiar with and comfortable funding expert consultants through

their grant vehicles to ensure tribes have access to the highest quality assistance available.

DEMD personnel have many years of experience with all phases of CEB housing projects, and

any tribe considering CEBs as a solution to their housing issues should contact the department.

Soil Testing

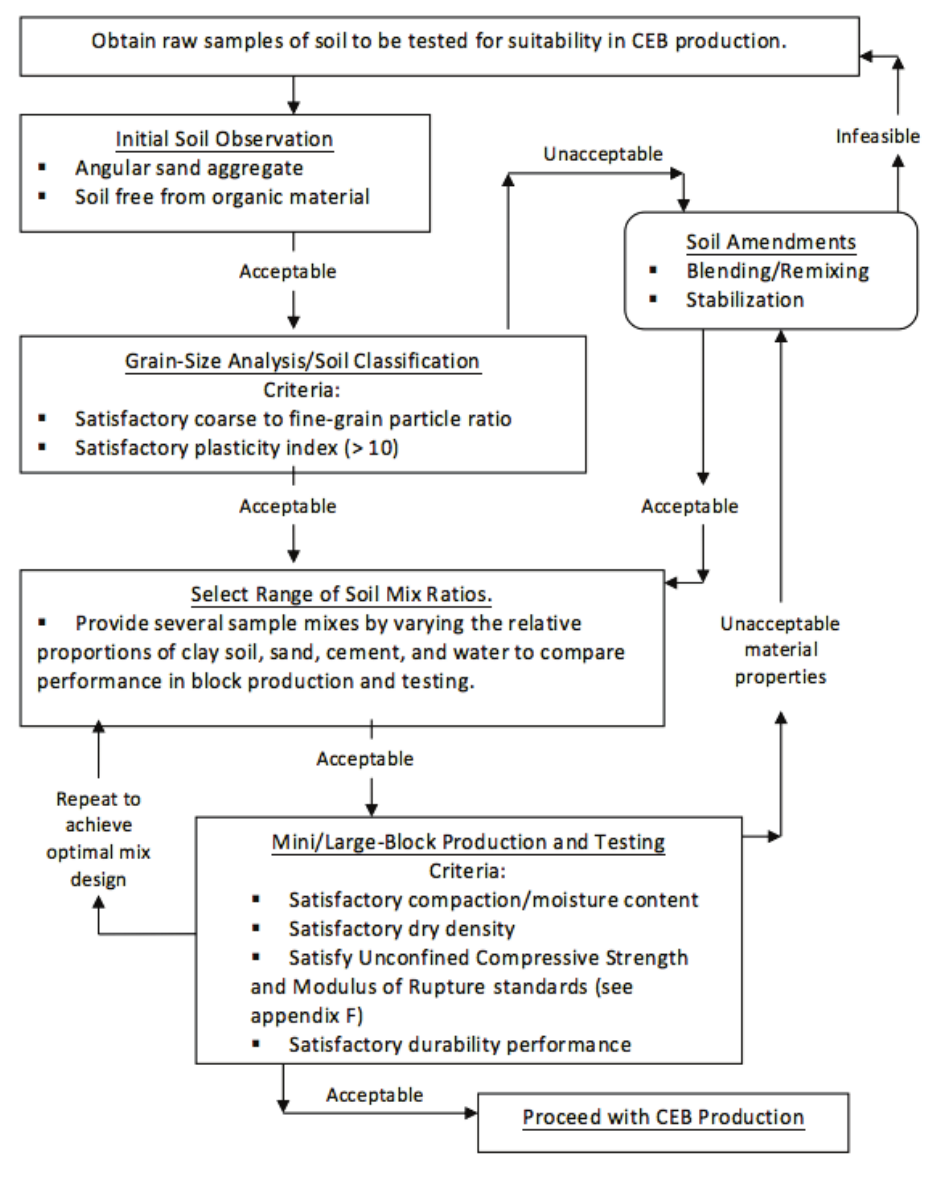

A synopsis of the recommended soil identification and testing process follows:

• Contact DEMD to perform preliminary materials evaluation at multiple locations—

recall that soil properties will vary from site to site as will extraction costs related to

access, reclamation, and transportation. So the number of different sites sampled should

be roughly equivalent to the number of these significant variables influencing the final

selection.

• A geologist will extract about 200 pounds of clayey soil from minimum five sites for

further laboratory testing. Many of the soil tests and subsequent experiments on sample

CEBs are destructive and soil materials cannot be reused. Provide sufficient material to

the lab so the testing process is not interrupted and the sampling integrity (site specific)

is not compromised.

12

http://www.bia.gov/WhoWeAre/AS-IA/IEED/DEMD/.

10

• A qualified laboratory will perform systematic soil analysis on all samples determining

initial moisture content, classification, plasticity index, and hydrometer tests for finer

grained soils (clay content).

• Using samples from the remaining viable sites, the laboratory will produce CEBs with

varying ratios of clay soil, sand, and water,

13

with some samples including lime or

cement as stabilizers. These samples are cured and performance tested at predetermined

intervals over the course of 28 days (usually after 7, 21, and 28 days).

• Approximately 250 to 350 CEBs will be made and tested for wet and dry compressive

strength, freeze/thaw durability, moisture absorption capacity, and modulus of rupture,

along with others depending on the analysis of specific sample performance.

• Using preliminary laboratory results, the geologist will then develop and implement a

more comprehensive subsurface sample collection plan, which will include preliminary

mine planning, permitting, and extraction/excavation site layout.

• The conclusion of the analysis of the test data will include a ranking of the sites based on the

quality of the material and the preliminary cost to produce stabilized or unstabilized CEBs

from each site. The economic assessment at this phase is limited to the information from the

test data. Subsequent economic analysis (typically performed by DEMD) will incorporate

specific mining, hauling, reclamation, and yield estimates from each suitable site.

A testing matrix developed by researchers at the University of Colorado is provided in appendix A

(Krosnowski, 2011). Sand generally requires less rigorous testing, although knowledge gained

from visual inspection should be supplemented with a simple grain size sieve analysis to

determine its grade. Sand that is too fine, too coarse, or too similar in grain size throughout the

sample is unsuitable for CEB production.

Excavation and Hauling of Soil

In most cases it will be necessary to retain a contractor to perform the mining of the soil and

subsequent reclamation of the pit. Before that, you must obtain a bulk sample permit through the

regional BIA office following a National Environmental Policy Act

14

review of the site for

environmental compliance and also, appropriately, a tribal archaeological review. To justify the

extent of paperwork, 1,000 cubic yards is a reasonable minimum sample, although the upper

limit is 5,000 cubic yards. Depending on the ratio of clay soil to sand you determined for your

CEBs, this volume of material, combined with the proportional amounts of the other ingredients,

will yield about 20 houses worth of CEBs.

13

A note on water content of CEBs: Water is a critical factor affecting the long-term performance of CEBs. A mix

too wet will leave excessive void spaces with evaporation increasing the potential for moisture absorption at a later

time and weakening the compressive strength of the block. Too little water inhibits the binding competency of the

clay and may result in poor internal cohesion and block density. The lab tests will identify optimal water content for

manufactured CEBs. In the field, outside the controlled climate of the lab, water ratios must be adjusted based on

production site characteristics such as relative humidity, dry soil storage wind and sun exposure of the mix, and

quality of mixing equipment because poorly kept equipment can influence volume calculations.

14

http://www.bia.gov/cs/groups/xraca/documents/text/idc009157.pdf.

11

Although this permit process follows its bureaucratic course, you should then seek a qualified

mining contractor and define the SOW. The contractor’s SOW should essentially follow the

14-point Bulk Material Sampling Process Guide found in appendix B. Define the SOW to

address specific conditions relating to material locations, transport routes, and other local

concerns and considerations. It is important to insist on performing any soil and sand screening

at the mine site, thus paying only to transport the useable material to the CEB production plant

and reserving the “waste” for later use as mine fill and reclamation material. (Both soil and sand

should be screened to 1/4 inch minus for optimal mixing and binding, and sand should be of

fractured face rather than rounded aggregate for CEBs.) In addition, qualifying the contractor

selection by their experience in onsite material separation is a great benefit. A skilled excavator

can significantly limit the waste material being removed, focusing only on the soils valuable to

your project, thereby reducing the amount of time and expense in the screening process. Include

specific language related to experience and capability that help achieve your efficiency goals in

the scope for bid documents included in the procurement process. By the same token, it may be

worth requiring the use of a pup trailer as shown in figure 5 or identifying a minimum haulage,

consistent with roadway or bridge capacity, to reduce the number of trips from mine site to plant.

Mileage charges are often the bulk of the costs for hauling. Alternatively, if storage space at the

plant is limited, leaving the soil secured at the mine site and arranging for loading and delivery

through the Tribal Roads Department or another local contractor interested in “fill-in” work

during slow periods might serve you well. Determining your requirements during this stage of

the process with the contractor providing the services will make managing your project budget

less stressful.

Figure 5. Truck and Pup

12

Production of CEBs

The Crew

Having found the right soil and determined the best mix or recipe, you will then need to

develop the production facility, train the crew, and acquire the equipment. The crew is the

most important piece, so this is the logical starting point. The production lead should be hired

first, as that position requires specific experience with machinery, crew supervision, and

ideally, working with production schedules and budgets. The background and work history of

the production lead will help with the recruitment and hiring of the remainder of the crew. In

general, a competent, well-organized, and motivated crew of six can produce between 1,500

and 2,000 CEBs per day using a single hydraulic block-making machine. Although this level of

efficiency is achievable and economically desirable, the more important objective is quality,

rather than quantity. In masonry, a wall is only as good as its weakest brick (or CEB, in this

case)—a block will perform only as well as the block it is stacked on permits. The process of

making CEBs is simple, but not easy; the hardest part is not permitting small errors to

compound into larger, more serious ones. For this reason, it is important to invest the

appropriate time and energy into selecting the project’s labor resource, on a similar scale to the

facilities and equipment. Recall that one of the goals of the project is to expand employment

opportunities on the reservation when making your selections.

Although CEB manufacture is a labor-intensive job, brute force alone will not produce a quality

product. Following a structured process, taking all the steps in the right order, and insisting on

quality control at each stage of the operation is the safest way to ensure that the CEBs produced

belong in tribal homes. Consistency in the mix is one of the most crucial elements in maintaining

the high quality of CEBs produced. The ratios of the mix components and the thoroughness of

the mixing should be double-checked as a matter of procedure. A poorly mixed block can look

just like a good block coming out of the machine—problems may not show up until the CEB has

been used in a home’s wall. Responsibility for CEB production oversight is best assigned to

someone not prone to seeking shortcuts in their work. Appendixes D and E include a list of

recommended roles and responsibilities for a CEB manufacturing team.

An optimal production crew size is six to seven people: three people on the CEB maker; two

people performing the bulk mixing and loading of the batch mixer (where final water and lime

or cement is added); and one person wrapping, labeling, and recording batch numbers, dates,

and additional information for inventory control, and moving pallets to the curing location. An

optional seventh crewmember could be responsible for quality assurance by testing blocks

from random batches, ordering supplies, and filing in if production levels justify the added

expense. While one of the goals of the materials manufacturing/construction project is to

increase employment on the reservation, overstaffing with the sole purpose of employing

more workers is counterproductive to this objective and the larger mission of sustainability

and self-reliance. Operational efficiency will ultimately lead to greater employment, but this

can only be accomplished if the project output (benefits) matches or exceeds the project

costs. You should achieve these employment goals through long-term job security and career

opportunity rather than by providing temporary pay to more workers. In addition,

overstaffing can result in reduced individual performance and increased downtime,

negatively affecting crew morale. If the CEB plant is perceived as providing only temporary

13

jobs with few future prospects or hope for advancement, the project will attract only

applicants seeking that type of work. This approach is not the foundation of a sustainable

business enterprise.

Cross training, interning, and apprenticeship should be the centerpiece of your human resources

investment plan. It is far cheaper to keep current staff than it is to hire and train new employees.

Turnover in a workforce is inevitable. Rotating the crew through all work facets and providing

instruction and opportunity for them to use and to become proficient with all the equipment can

minimize the cost of attrition.

Expanding the skill set of your crew and encouraging them to teach and train others through

internships and apprenticeships improves their own knowledge, competency, and value, while

increasing their loyalty and commitment to the project. At the same time, you will be identifying

future crew prospects and spreading the benefits of the project more widely throughout the

community. The most successful profit-oriented businesses recognize that it is far cheaper to

retain quality employees through benefits, perks, and incentives than to recruit, hire, and train

new ones. Though the budget may not be able to support increased wages, ensuring a safe

working environment with acceptable facilities and conditions and offering increased

involvement in achieving the broader objectives of the project are indications to the crew of how

valuable it is to the overall mission. In essence, your projects goals should align with those of

your employees and vice versa.

Production Site

When selecting a site for CEB production, it is important to consider the effect of distance on the

cost of transporting both of the raw soil materials to the facility and the final product to the home

sites. Consider the quality of nearby roads and their predominant use (it may be better not to

locate in a school or hospital zone, for example) and access to sufficient power and water to

support both the CEB production and the maintenance of the equipment and facility. An office

area equipped with a small lab and typical business supplies for coordinating and tracking

payroll, reporting, and inventory control on the production site keeps the management and crew

working together. Nothing seems to poison a crew’s moral faster than the idea that management

has substantially better working conditions than they do. By the same token, demonstrating

solidarity and a commitment to working beside a crew, and getting your hands dirty, can inspire

peak production. It enables better monitoring and adjustment toward improved efficiency.

The production yard will function much like a traditional brickyard or timber mill.

15

An ideal

yard would be 300 by 300 feet, leaving plenty of room for a circular unloading and loading

corridor around the perimeter of the production and handling area. If possible, the design should

include a dedicated entrance and a separate exit. It is better to off-load and store raw material

close to the entrance and to store finished CEBs toward the exit, with a loading platform in place

to expedite the transfer. Loading CEBs will take longer than the dumping of the soil and sand, so

set up an area outside the traffic flow in the yard. Your onsite capacity to store material and

finished CEBs is vital for managing site access and traffic pattern. An important material storage

concern is sheltering the soil, in particular, from excess water. Store only the material you are

15

http://makebricks.blogspot.com/2012/11/brick-making-yard-layouts.html.

14

capable of keeping covered, otherwise, too much time and (paid) effort will be spent trying to

dry out the soil to the proper water content for the mix. In addition, the mixing area and CEB

production machines should be near the end of the site where your material is stored, and

finished product should flow toward the other end of the site. You should cover this area as well

to protect the machine, the mix, and to minimize inefficiencies due to adverse weather effects on

the crew. Laying out the yard carefully in advance of material delivery and equipment setup will

prevent moving material within the site more than necessary, saving time and money.

Equipment

The process of making CEBs is essentially manipulating loose soil into compacted blocks. This

process, of course, has been done by hand for millennia. Alternatively, using the advantages

gained through hydraulic power and diesel-fueled machinery can dramatically increase the

production rate. It is a safe bet that most U.S. funding agencies support a more modern pace of

manufacturing to supply an equivalent pace of home construction. A group of 20 houses require

about 100,000 CEBs. At a conservative estimate of 1,500 CEBs per day and accounting for

downtime of equipment and crew and setup you will need nearly 4 months of steady efficient

production to achieve this rate of production. If you have experience with similar endeavors, you

might anticipate the unknown but all-too-likely unscheduled interruption, and thus, may choose

to temper your performance commitment. A reasonably robust production schedule warrants

taking advantage of modern material handling equipment and higher yield CEB machinery.

Handling the soil is best achieved using common landscaping and excavation equipment like

Bobcats and small tractor loaders. The Bobcats can be accessorized with removable forks for use

with pallets also, which reduces the initial investment burden. A robust production scale will still

require two Bobcats, with one supporting the mixing and loading of raw soil and the other

moving pallets of manufactured CEBs from the machine and loading CEBs for homesite

delivery. You will need a lift at the home site to unload also. If transporting a forked Bobcat

from the plant to do this work, consider timing the delivery so no interruption in production

occurs. I advise that the course dry mixing of clayey soil and sand with the Bobcat take place in

an area near the block-making equipment, preferably on a slab rather than dirt ground to avoid

scraping organics into your mix. Proportional mix ratios should be checked frequently as using

Bobcat buckets (that is, three Bobcat buckets clay to one Bobcat bucket sand) invites potential

error —the mix design is based on weight ratios rather than volume. It will be important to verify

the relative yard weights of Bobcat buckets of clay and sand.

16

CEB manufacture at production scale does require some specialized equipment. After combining

the dry clayey soil and sand, this mix should be loaded into a mechanical mixer to which the

machine or workers can add the proper ratios of lime or cement and water. Quality mixers have

direct water feeds and a meter to measure the volume. See figure 6 for an example. Typical CEB

mixers will have a built-in auger that evenly distributes the ingredients and then expels the mix

through a chute at or near the bottom. Modifying the positioning of the mixer by elevating it or

16

Yard weight refers to the material weight in the storage location, which includes the material’s capacity to store

ambient water. Clay will store substantially more water than sand, and will absorb and desorb water during the

course of the day. The step does not only add the water weight variable to the volume, but may also result in gravity

compaction within the bucket as well. The concern is obviously greater in higher humidity areas. Still, weight to

volume ratios, and soil moisture content should be checked frequently as part of a good quality control regimen.

15

by locating it near a drop-off or collection trench can increase efficiency; the Bobcat can scoop

the mix and load the block compression machine. Choose your mixer and compression machine

for compatibility, as one should not significantly outpace the other. In particular, the mix should

not sit while waiting for the compression machine to catch up as moisture may evaporate and, if

using lime or cement, the curing process will have already begun. Similarly, the CEB crew

should not be standing around waiting on a mix. The crew should clean the mixer daily,

particularly if using lime or cement. Ideally, a worker uses an air compressor and sparingly, with

water to accomplish this task. Any residual cement will harden if water is left in the mixer to

activate it. It is advisable to charge the two of most responsible crewmembers with maintaining

the safe and efficient functioning of the mixer and the block maker. One lost day of production

because of malfunctioning equipment will quickly justify this additional attention.

Figure 6. Advanced Earthen Construction Technologies (AECT) MX20 CEB Mixer

Many types of CEB production machines exist. The cost of labor and the number of CEBs

needed often determine the maximum feasible investment in the equipment. A large hydraulic

press machine is best suited for a multiple home construction enterprise. During efficient

operations, a quality CEB machine will not be the limiting factor in the production rate. Many

newer machines can produce six to seven CEBs per minute depending on size. In general, the

crew’s inability to keep up with the mixing, loading, handling, and storing of the CEBs will

restrict the output. This result is as it should be. The crewmembers should concern themselves

with quality before quantity and should be sized to slightly underperform the equipment so that

the likelihood and thus cost of idle time is minimized. Figure 7 shows a transportable model

CEB machine made by Advanced Earthen Construction Technologies.

16

Figure 7. AECT 3500 CEB Machine

The CEB machine should have a top feed hopper large enough to accept a full Bobcat payload of

the soil mix. It should be capable of applying a minimum ram (compressive) force of 1,200 psi

with rapid cycle recovery. Many models are built on a trailer chassis for easy transport, which

can be particularly advantageous if you are considering making CEBs at the home site. In

general, like other machinery, the model should be industry hardened through years of

production and use. It will be a significant investment in the range of tens of thousands of dollars

for a high capacity production unit.

Other valuable features you should consider when buying a CEB machine include simple

electronic controls and servo valves for the hydraulic operation, easily calibrated electronic eyes

for setting block thickness, multiple dies for producing different size blocks, and accessible

components for easy cleanup and maintenance.

Most large CEB machines come with at least 10 feet of nonmotorized rollers moving the blocks

away from possible congestion. It is advisable to orient the blockmaker so that CEBs can be

loaded onto pallets with minimal handling and in the direction of the curing area. Stack pallets

on makeshift CEB walls so workers will not have to bend over to load them—the forklift can

pick the pallet up without suffering a sore back. Weight limits on the pallet should reflect the

handling capacity of the lift rather than the rating for the pallet. The CEBs can handle being

stacked. Consider this attribute when selecting an area for curing and storing. A larger footprint

will be required if vertical stacking is not feasible.

CEB Curing and Inventory Control

Before initiating the CEB production process, identify a location for block storage that is easily

accessible by forklift and accommodates stacking and rotation of stock. Make sure to keep this

space above freezing temperatures. Following the practice of first in, first out is sensible,

although it is of more importance to keep accurate records of batch numbers and production

dates should problems arise at a later time. Early in the production cycle you will want to rotate

the stock, moving to the newest product to the rear and the oldest forward. CEBs can be used in

17

construction as soon as 7 days after manufacture, but will continue to cure to their ultimate

strength for about another 21 days. If you plan to start construction inside this timeline, minimize

downtime with careful tracking and stock rotation while the CEBs cure. It is advisable to

perform thorough testing on fully cured CEBs (minimum of 28 days) and with a proven mix and

manufacture process before using any CEBs in construction. Partially cured CEBs should only

be used when the site manager has absolute certainty in the quality output of production and in

response to an urgent situation that does not permit time for the product to fully cure.

Develop and use an inventory tracking method—the less complicated, the better. The goal is to

distinguish poorly made CEBs from quality ones at the smallest possible scale to save time and

money. In the midst of steady production, it is always possible that a step in the process might be

skipped or a calculation error made. The purpose of quality control tracking is to catch these

errors before the resulting problems compound. Track inventory on a scale refined to the finest

point of significant influence on quality. For CEBs, this point may be at the batch mixer where

cement or lime and water are added. Label palleted CEB bundles with the date of production,

mix ratio, lot number that corresponds to course dry mix of clay and sand, and a batch number

that identifies the exact mix proportions of cement or lime and amount of water added. Record

these notations in a production log that is updated as the product cures and then leaves the

warehouse for the home site.

Testing of CEBs is required by various code agencies like the New Mexico Building Code,

17

the

first code authority to incorporate CEBs. The New Mexico Building Code requires testing at the

rate of every 5,000 CEBs produced. In the early stages of production when the learning curve for

the crew remains steep, it is advisable to test more frequently, perhaps every 500 CEBs, or more

often if quality is inconsistent. This approach to testing will also inform you on the influences of

each of the various factors that go into the specific production process for your CEBs and help

you identify the best scale for tracking your inventory. A failed test occurs when the blocks

cannot sustain compression greater than 300psi. At that point all blocks within the finest scale of

tracking should be destroyed and sample blocks from every batch within the next recorded level

up must be tested. Having to discard a significant number of CEBs that underperform the

standard will fine-tune the crew’s attention to detail and focus everyone on the importance of

quality control and consistent recordkeeping. If you are making SCEBs, you should fully

submerge five of them in a bucket of water after they have cured for 7 to 14 days and monitor

any deterioration (melting). If melting is evident, similarly test SCEBs that have cured for 28

days and monitor them. A testing sample matrix is included as appendix f.

As CEBs leave the production facility, make sure the inventory log includes an update that

reflects in which home they will be used. Include any comments on their arrival condition or

performance at the jobsite in the notes section within the log. The log itself should be the

responsibility of the production supervisor with loss reports provided to the PM at regular

intervals. Inventory and quality control are crucial steps in ensuring a sustainable manufacturing

enterprise. The investment in this aspect of the production process should reflect the commitment

to the success of the larger project.

17

http://164.64.110.239/nmac/parts/title14/14.007.0004.htm.

18

Also consider the management of waste byproduct generated during production and security of

the facility, equipment, and successful or failed inventory. CEBs that fail structural testing

should be destroyed and removed from the production site immediately. These rejected CEBs

can be used productively as a clean, nontoxic landscaping fill to control onsite drainage. Be sure

they do not reenter the inventory stream.

Design and Construction

From an architectural perspective CEBs offer similar form and functional qualities as brick,

stone, and other masonry units. CEBs are more easily cut than stone and are more durable and

stable than adobe and wood. They offer nearly limitless functional design possibilities for home

construction. The many enduring ancient earthen structures around the world today speak to the

lasting structural integrity that earth blocks can achieve while simultaneously showcasing the

wide varieties of form and the artful grace they can provide. The structural integrity of the CEBs

allows us to use them as a structural wall system that requires minimal reinforcement or

additional framing.

I will address some design advantages and specific construction practices for CEBs in the

sections to follow. These recommendations are general principles and guidance for using CEBs.

It is advisable to engage professional architects and structural engineers, and to understand and

design to all applicable building codes before initiating construction.

Design Considerations for Building With CEBs

A number of aspects particular to CEBs influence both the practical and aesthetic design of a

house. The capacity of CEBs to absorb and radiate solar energy as heat is one of its great

advantages. First, I recommend siting or orienting a house on its lot (as well as coupling this with

energy efficient design elements) to take greatest advantage of passive solar energy. Using the

seasonal pattern of the sun’s trajectory, a CEB house could have large south-facing windows or

sliding doors that enable sunrays to penetrate the house interior. You can use passive solar

energy in a CEB trombe wall and a thermal mass floor during the winter months when the sun is

lower on the horizon. The trombe wall and floor will radiate this energy as heat long after the sun

has set. A long sloping roof overhang will shade these same windows in the summer months

when the sun is more directly overhead. An exterior wall of CEBs will absorb and reradiate

energy as well. The local climate and lot conditions should instruct the design characteristics of

each CEB home. Custom design and construction is probably not economically feasible for most

tribal housing projects. Mirror image layout of similar designs and modifying each house

orientation on different lots can often resolve property configuration and siting challenges while

still achieving the goal of energy efficiency. Considering the energy-storing capacity of CEBs is

crucial to maximizing their value in home construction.

In colder climates, CEB and other masonry structures are often built with two parallel interior

and exterior walls separated by a sealed air or insulation chase (see figure 8). This double-wythe

wall system is designed to create a full thermal divide between the outside and inside walls to

keep the cold out and the warmth in. This system results in a thick wall that requires twice as

many CEBs and results in reduced interior living space for a given foundation footprint. Building

19

with CEBs in cold climates will require a design that balances the local code-based insulating

requirements for homes with the comfort and aesthetic preferences of the occupants. A single-

wythe wall would require insulation on either the outside or the inside of the wall. In each case,

losses of other performance or aesthetic characteristics of the CEB wall may occur. If one of the

goals of the construction project is to unburden homeowners of high-cost energy bills, preventing

heat loss or cold intrusion through adequate insulation is likely the best means of reducing the

need for mechanical conditioning of the indoor living space. The additional capital investment in

CEBs for a double-wythe wall system may pay for itself in the savings earned by lowering

energy demand.

Figure 8. Showing Double Wythe Wall Diagram With Insulation Chase

20

Overview of the CEB Construction Practice

Foundation

The heavy CEB house will likely require overexcavation of the foundation site. This hole will

then be filled with free-draining material and compacted based on the material’s proctor value to

form a subfoundation (figure 9). The finished elevation of the home’s floor should be well above

the grade of the rest of the lot. Even stabilized CEBs are susceptible to some moisture intrusion.

Any water from rain, snow, or irrigation should move quickly away from the house by gravity

force alone. After the final backfill, make sure subsequent grading around the house is strongly

positive. Poor grading of the lot resulting in negative drainage may undermine the foundation by

washing away portions of this subfoundation soil. Any settling of the foundation in excess of one

inch of relative displacement can cause structural failure in the CEB masonry, with other issues

compounding from that point. It is thus a good idea to retain a geotechnical engineer to sample

the soil conditions at the site and make recommendations relating to the foundation and area

drainage.

Figure 9. Over-Excavated, Compacted, Filled, and Shaped Subfoundation

Working now from the ground up, the foundation must be designed and built to support a heavy

house. A single 4-x-10-x-14-inch CEB will weigh about 45 pounds. The foundation or footer and

stem wall must be stout enough support a stack of 20 or more of these for the exterior wall. If

building interior walls of CEBs, the slab must be thickened at each wall location or a grade beam

used to properly distribute the load throughout the foundation structure. A structural engineer

should review drawings or plans as wind loads, seismic zones, and other considerations influence

the bearing capacity and foundation design.

In areas susceptible to heavy snowfall or drifting, be sure to use concrete masonry unit (CMU) or

a similar material in the first vertical foot of exterior wall. In the Rocky Mountain West, it is not

21

uncommon to have drifting snow accumulating against houses during a storm one day, and the

brightest sunny day the next. The sun will heat the exterior CEB wall, melting the snow and

exposing the CEBs to significant surface moisture, with some of this water being absorbed by the

block. At night, colder temperatures may cause this water to freeze and expand, causing typically

minor, but notable issues. Repetitive cycles of this scenario are cause for concern and will

necessitate a design solution. Obviously, the lower courses are more vulnerable to this scenario.

Generally, using CMU for the first vertical foot is adequate protection. Although stabilized CEB

walls can withstand nominal moisture exposure, plastering the walls with a coating or two of

similar material is advisable. One can easily make any subsequent repairs, as the mix is available

locally. For higher moisture climates, a three-coat cementitious plaster layer affords more than

adequate protection from the elements.

CEBs are, by design, dense and hard to penetrate with standard construction tools, unlike the

more common wood frame hollow-wall houses. Therefore, integrate the foundation plan with the

electrical, plumbing, and mechanical detail so that, if desired, service supply lines can be brought

into the house under or through the foundation and floor. If pouring a slab, setting the interior

stubs with precision beforehand will save a small fortune in expense and anxiety if relocating is

otherwise required.

Building Up the Walls

After the foundation has been completed, layout for doors and windows, and block walls can

begin. Proper procedure requires that the foundation be checked for square first. A square or

rectangular foundation can be verified as true by simply measuring the diagonal length from

opposing corners. For foundations with more than four straight sides, use the longest 3, 4, 5 right

triangle multiplier possible.

18

From each square foundation corner measure 3 feet along the edge

and make a mark. From the same starting point, measure 4 feet along the other axis and mark the

foundation edge again. Now, carefully measure the diagonal distance between those two marks.

Any length other than exactly 5 feet means the foundation is out of square and you will need to

adjust the alignment of your blocks in reference to the foundation line to compensate. Use a

multiple of the 3, 4, 5 triangle for longer walls. For example, try 6, 8, 10 or 9, 12, 15, if the space

exists. If adjustments are needed, choose a single reference point that is easily observed and

accessed and pull all measurements from that location. Where possible, snap chalk lines to

indicate the first course layout location. Consult with the project architect or engineer for ways to

compensate for out-of-square issues before laying block.

Marking the location of exterior doors on the foundation is the next step. Door and window

openings are framed with “bucks” that act as a form for the rough opening (RO) of blocks

(figure 10). Install door bucks before laying your blocks. Bucks can be made of welded steel that

will provide a sturdy reusable frame. Wooden bucks perform equally well as the steel for shorter

term and one-time use or they can be left in place to serve as nailing points for door or window

frames and trim. Determine the intent to either leave the bucks or remove them before sizing the

RO for your doors and windows. The bucks will need to be diagonally braced to keep them square

18

The method is based on Pythagoras’ geometric theorem that the square of the length of the hypotenuse of a right

triangle is equal to the sum of the squares of the lengths of the other two sides. In equation form: 3

2

+ 4

2

= 5

2

, or 9 +

16 = 25. It is true for the multiples of the two sides that make up the right angle also. 6

2

+ 8

2

= 10

2

, or 36 + 64 = 100.

22

and prevent them from bowing during block setting. After the walls start rising, the doorway will

be the main access into and out of the interior of the house. Consider this aspect when setting and

bracing the bucks. Follow the door manufacturer’s guidance on the RO dimension.

Figure 10. Window Bucks Installed

After the door bucks are set, the first course of CMU blocks or CEBs, based on the design for the

area climate, can be laid directly on the foundation. For CMUs, this step is usually done with

cement or mortar. For CEBs, a contractor grade construction adhesive affords the best bond

between the concrete foundation and the CEB. Cement adhesive will work as well. Most

traditional masonry techniques, like staggered joints and woven corners, are applicable to CEB

construction. One specific variation from typical masonry practice however, is how CEBs are

bonded together. Rather than using a traditional cement mortar, CEBs adhere using wet slurry of

the same mixture they are made of, creating a monolithic wall after they have cured. It is very

important that the block surfaces to be bonded are moist during curing of the slurry. This

approach ensures a firm, lasting bond. The slurry should be made with finer grained sand than

the CEBs themselves, with particle size no larger than 1/8 inch. A 1/4-inch stone in thin slurry

joint may cause a point load on the blocks as more courses are added, potentially resulting in

cracking and spalling. A nominal 4-inch CEB should have a net thickness of 3 3/4 inches. With a

slurry mortar joint of 1/4 inch, three courses should raise the wall 1 vertical foot.

Story poles (figure 11) are used to keep the block courses level and the wall plumb. An 8-foot

length of 1/4-x-2-x-2-inch steel angle-fastened and braced at the foundation corners is marked

for each course and a mason’s line is stretched tight and level between the two poles. Working

out of the corners toward the midpoint of the two sides, two, three-person crews can have the

exterior walls of an average size house up in 2 or 3 days. Stacking CEBs and mixing the slurry

requires minimal technical skill, which makes this type of construction well suited for self-help,

23

sweat equity homebuilding projects. Like all construction projects, masonry practice and

building with CEBs have their challenges and issues. For this primary reason, among others,

it is advisable to have an experienced mason oversee this aspect of the project. Temperature,

humidity, wind, and sun affect the water proportion and curing rate of the slurry. A skilled

mason will know how to adjust and fine tune the slurry to ensure a quality bond in most weather

conditions. CEB masonry is not well suited for work in temperatures less than 30 °F. In some

cold weather cases, the slurry water can be heated to compensate for low ambient temperatures,

but this approach is risky, particularly if the CEBs are stored outside as well. In these instances,

an experienced mason makes the decision as to the prudence of continuing or delaying the work.

Figure 11. Orange Story Pole at Corner Bolted and Braced to Foundation

After reaching the final course, install window bucks up to the bottom sill. Unless the openings for

the windows and doors are structurally arched, span them with a solid lintel header like in

traditional masonry practice. The sill can be made of stone, steel, wood, or another suitable

material. The thickness and the acceptable span length are based on the choice of material, its load

bearing capacity, and the required performance of the wall itself as part of the larger structure.

A bond beam is typically used at the top of CEB walls, including interior walls, to tie them

together for stability, while also providing a leveled surface to which the next floor, roof rafters,

or trusses to attach (figure 12). Concrete or wood beams can be used for this purpose. A concrete

bond beam is typically poured in place after a somewhat complicated formwork and rebar

installation process has been completed. This process has the benefit of creating a single beam

without any separate segments that essentially envelopes and secures the entire wall system into

one piece. A properly sized wood beam can achieve sufficient wall stability, but will require

angle and gusset plates to join the segments together. Wood may be preferred if the bond beam

will be exposed as an architectural feature or if a companion goal of the project is a reduction in

the use of concrete.

24

Figure 12. Finished Bond Beam With Shed Roof Framing

In general, building codes and structural engineers will require that any forces imposed on a

building (wind, seismic, live and dead loads) must be transferred to the foundation through a

direct connection. Currently, CEBs are code approved as elements of compression resistance, but

do not provide shear resistance to lateral loading. To address this issue, structural engineers often

design a system of vertical rods poured in place at the interface of the foundation and the interior

side of the exterior wall. Engineers size and space these rods at intervals along the wall based on

wind and seismic ratings for the geographic location of the house. If bond beam is poured

concrete, these rods can be made of rebar and tied into the reinforcement within the bond beam.

For a wooden bond beam, all-thread rods that extend through the beam and are fastened down

with nuts will probably work best. If the house is of double-wythe construction, these tension

rods will be hidden in the chase between the two walls. If you are using a single-wythe wall,

locating these rods to engage a structural bond beam will require creative design to avoid

significant construction challenges and aesthetic impacts.

CEB construction is easily integrated into traditional housing design and construction methods.

Wood plates attached to the top of a concrete bond beam with adhesive and embedded j-bolts

enable the gable framing and rafter or truss to be attached. “Gringo blocks,” usually 2-x-4 lumber